|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

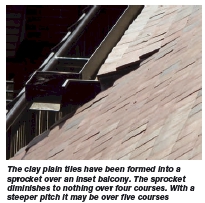

Plain tiles that have a camber in their

length are designed to only touch at the head and the tail on the

underside and be rested upon 100mm up from the leading edge by the tile

above, so the tile has to be relatively thick to provide the rigidity it

needs. Therefore plain tiles are able to cope when tiles are not laid in

the same plane, provided the true pitch of the eaves tile is not below

25º (rafter pitch less true tile pitch). This means that, to form a

sprocket at the eaves, the rafter pitch will need to be much steeper

than the normal minimum rafter pitch of 35º.

Where roof slopes meet at valleys and hips, the

sprocket will have an effect on the fit of the arris/curved valley tiles

and the arris/ bonnet hip tiles. Hips may require bedded hip (ridge)

tiles, and valleys may require an open lead valley to be used. If an

arris valley tile is specified it may be possible to mitre cut the

valley with lead soakers at the sprocket, and similarly with arris hip

tiles at a hip. Where one roof slope has a sprocket and the adjacent

does not, then it is not advisable to install valley tiles or a mitred

valley or bonnet/arris tiles or mitred hips. An open lead valley which

will change direction and bedded hip (ridge) tiles that do the same

thing will be needed.

Interlocking tiles

With interlocking tiles, the relationship between the top surface of the

lower tile and the underside of the upper tile is critical to allow the

weather bars to perform their function of preventing wind driven rain

from blowing in between the tiles.

If one course of tiles lays at a steeper true

pitch to the course of tiles below, only the leading edge of the tile

will make contact with the underside of the tile, reducing or preventing

the weather bars from performing their function. Above 30º this may not

be an issue, but below 30º it will have a detrimental effect. For tiles

that can be laid down below 20º it is critical, as gravity is not

working in your favour, but the true tile pitch should never be any less

than 5º below the minimum rafter pitch for that design of tile.

Tiles that only need to be nailed, or not fixed at all, at

the eaves sprocket may not present a problem, but where the second and

third course of tiles need to be clipped, the length of the clip from

the batten to the side interlock will increase, requiring a longer clip.

In some cases where it is a tile-to-tile clip, it is impossible to fix

unless the tiles lay in the same plane, and therefore impossible to

comply with the manufacturer’s fixing requirements.

While it is tempting to fit a clip for another

tile or from another manufacturer, the performance of that clip in that

situation will be unknown, so calculating the wind uplift resistance

will be difficult without test results for that combination of tile,

clip and pitch difference. The relationship between the tiles on each

subsequent course will be different, making the clip length and hook

angle different.

As with plain tiles, where roof slopes meet the true

pitch of the hip and the valley will also be affected. If the true pitch

of a hip or a valley is approx 5º less than the rafter pitch it is

possible that with an open lead valley that the width of the open

channel over the length of the sprocket will need to be widened, as the

water flow will tend to back up unless the capacity is increased, making

GRP valley troughs unsuitable.

Also, if it is decided to change from a GRP valley

trough to a lead open valley for the length of the sprocket, the amount

of lap of the lead up under the GRP needs to be taken into

consideration. Unless the true pitch of the valley is above 30º, the lap

will be more than 150mm. If the true pitch of the valley is 11º (rafter

pitch of 15º), the lap will be 390mm; if the true pitch is less than

11º, then the valley is too shallow to allow for a lap in the

construction. It would be better to avoid a sprocket on an interlocking

roof unless the true tile pitch is over 25º and tiles do not need to be

clipped.

Double lap slates

With double lap slates, either natural or fibre cement, a sprocket is

problematic, as unlike plain tiles, they are thin flat slabs that need

to be fully supported over most of their length. The slates should not

be laid below their minimum true pitch, which is approx 3º less than the

recommended rafter pitch for a given slate size, thickness, nail hole

position and head lap, for a given location. |

|

Because the slate is flat, if the

upper slate lays at a steeper pitch, only the leading edge makes contact

with the slate below and the top edge make contact with the batten. This

means that at the centre nail hole positions there is a large gap, which

means that a standard fixing nail is often not long enough to penetrate

the batten by the minimum 15mm. On each subsequent course, the nail

length required will be different. It is common for packing battens to

be installed against the head of the batten at the centre nail position.

For each situation, the thickness of the packing batten will need to be

measured and cut before being installed. Also, the nail hole position

needs to be moved approx 50mm up the slate to allow the slate to be

nailed into the packing batten with a standard slate nail. Using a long

nail into the lower slate batten is not a good idea, as it is very easy

to break the slate if over nailed at this point, and if left under

nailed will allow the sprocketed slate to rattle in the wind.

Slates at the eaves are always vulnerable to breakage

from tradesmen gaining access to the roof. But double lap slates on a

sprocket are more vulnerable to breakage at the eaves as they are not

fully supported and may be under stress if there is no central packing

batten. Even if there is, there is still a risk of breakage, as they are

not fully supported.

With fibre cement slates, where the copper disc rivet

is held between the slates, and the pin protrudes up between the slates.

With a sprocket the slates are not laying in the same plane, so the

copper disc rivet drops down onto the lower slate, reducing the pin

length that can be bent over. It is possible, with a pair of pliers, to

pull the rivet pin up before bending the rivet pin over at 90º, but it

is not easy, and the rivet may end up being loose. FC slates, when new,

are slightly more flexible than natural slates, so can be bent to a

slight curve, but will break with too much of a bend.

Conclusion

Provided the roof pitch is relatively steep and that the eaves course of

tiles are not laid below the minimum true tile pitch (rafter pitch less

tile pitch) and the tiles are nailed into position, then it is possible

to achieve a sprocketed eaves detail. However, with natural slates,

packing battens will be needed and there will always be a risk of slates

breaking at the eaves. Provided the sprocket is no more than 5°, FC

slates will cope with the sprocket. Overall it is a lot of extra work

and responsibility for little or no gain.

Tips

- Set out and measure the true valley

pitch before you construct the valley, as it may be impossible to

use most forms of valley.

- Order extra slates and slate hooks

to repair the broken slates that will occur at the eaves.

- Avoid using interlocking tiles in

windy locations on a roof with a sprocket.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|