|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

The term roof slate

is applied to any product that looks like, or tries to mimic, natural

slate. But unlike natural slate most products called roofing slate are not

laid like natural slate, as they are not double lap products

Single and double lap

Natural slate, being thin, flat rectangles of stone, are only weather

resistant when laid with a double lap giving the traditional half bond

appearance. Fibre cement slates and some resin slates are also laid in the

same way. The remainder of the roofing products called slates are

single-lap tiles, made from either concrete, resin slate, clay or metal.

Single lap slates require far fewer units per square metre of roof than a

double lap product. Between 70 to 50 percent of a roof slope covered with

single lap slates has one layer, with between 50 to 30 percent with two

layers at the head lap and side interlock. Natural slate has between 78

and 34 percent of the roof slope covered with two layers and between 66

and 22 percent with three layers at the head lap. This must not be

confused with the weight which tends to be greater with concrete slates,

due to their greater thickness.

In most instances the minimum rafter pitch

for single lap slates can be as much as 5° lower than for a natural

slate. The resulting reduction in rafter pitch, and material quantity,

added to the cost of the base material, makes single lap slates a very

cost effective roofing product.

On paper single lap slates out perform the

equivalent double lap slate. But single lap slates have some limitations

that should be considered before they are used in place of double lap

slates.

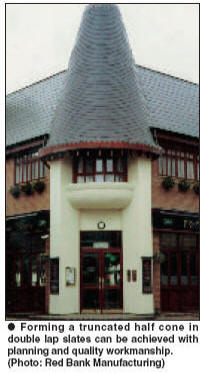

Curved Roofs

Single lap slates do not like going around any form of curve. Some can be

made to do so, but in most instances it will reduce performance to rain

penetration. This may result in a steeper rafter pitch being required. The

ability of double lap slates to be tapered to fit and available in a wide

variety of sizes makes them more ideal for curved roofs.

If the building is curved on plan, the number of slates needed on the

outside of the radius will be more than on the inside of the radius. In between the two

the number of slates per course will reduce. Because single lap slates are

a fixed width and rectangular, the half bond joint will drift until the

interlocks line up. Some designs will not allow any interlock drift at

all. Also on a large radius the shunt in the interlocks may allow a little

tapering, as the radius gets smaller the slates will become impossible to

lay without damaging or compromising the interlocks. Slates, being flat,

will form a tangent to the curve and produce triangular gaps under the

slates that will get bigger with wider slates and on tighter curves. The

upshot of single lap slates being only supported at the interlocks is that

interlock breakage will occur.

With a roof curve from eaves to ridge, single lap slates will either touch

along the leading edge or the top edge of the lower slate. Touching on the

leading edge may prevent some slate clips from fitting, as the hack is

high. Touching on the top edge of the lower slate can create a gap under

the leading edge, allowing wind driven rain to breach the head lap.

For

all these reasons it is not advisable to use interlocking slates on any

roof with a curve. A curved roof can be accommodated by dividing into a

set of facets, with each facet treated separately, with hip, valleys or

flashing between them.

|

|

Straight bond

To make an interlocking slate look like a natural slate, the side

interlock has to be positioned below the surface of the slate.

The

interlock acts as a small gutter, draining away rainwater. Like all

gutters they have a maximum capacity beyond which they will flood. In the

case of a single-lap slate interlock, it will be onto the underlay and

battens below. At the bottom of the interlock the water drains out onto

the surface of the slate below. With a broken bond the water discharges

into the middle of the slate. If the interlocks are straight bonded the

water will discharge directly into the next interlock. If water drains

down the interlocks in this manner, it will not take many slate courses

before the interlocks will reach maximum capacity during a rainstorm.

Long rafter length

A similar over capacity of the interlocks can occur with long rafter

lengths. The quantity of water washing off the slates at the ridge will be

added to the water falling on the lower slates. This accumulation of water

builds up as it reaches the eaves. The weight of water creates a pressure

that forces water through the interlocks onto the underlay and battens

below. The distance down from the ridge at which this will happen depends

upon the design of the interlock, roof pitch and volume of rainfall. By

increasing the rafter pitch, a longer rafter can be accommodated.

Unfortunately you may find that increasing the pitch will also lengthen

the rafter. The safest answer would be to change to another design of

interlocking slate or reduce the width of the building, which ever is the

easiest/cheaper solution Each design of single lap slate will perform

differently; consequently the manufacturer should be contacted for

recommendations. Major manufacturers include a table or formula in their

literature. Some smaller manufacturers may not be aware of the limitation

on their products as they have never undertaken any long rafter length

deluge testing to replicate a typical 'once in 50 year' UK rainstorm.

Decoration

Natural slates come in a range of colours from green, through blue to

black. In theory, man-made slates can be made in a much wider range of

colours to allow the creation of patterns on the roof. But if a pattern is

to be formed using ornamental slates, with a shaped leading edge, double

lap slates will need to be used as ornamental single lap slate are not

made.

|

|

Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|