|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

The external elevations as shown on an

architect’s drawing can look very clean cut with lines meeting exactly

at intersections, giving the appearance of precision and style. But in

reality things are never that precise. For instance at the intersection

point between two hip lines and a ridge, the ridge is rarely at the same

level. The same goes for slates or tiles installed in close proximity to

a soffit or fascia board, especially around a dormer. The draughtsman

can draw it but often it can be difficult to impossible to construct, as

there is no room to swing a hammer, or twist a screwdriver. In these

situations what should you do? Use common sense.

Side abutment

On a dormer the side abutment construction starts off quite

conventionally and as it gets closer to the valley the construction gets

more and more difficult. If there is no soffit then it is possible to

fix the top three courses of slates or tiles to the battens that finish

on the last rafter under the valley, through the rafter feet of the

dormer, which is not as easy as it sounds. Once the soffit board is

installed, that option is removed making the installation of the top

slates or tiles almost impossible.

With tiles that have nibs they are often not

nailed, but with slates this is not an option. Even where there is a

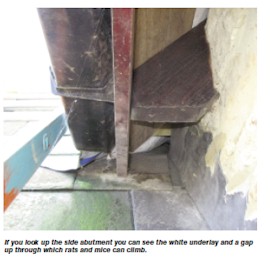

soffit, and always where there is no soffit, the point at which the

soffit and roof covering meet are ideal locations for birds to nest, and

it is often impossible to reach in to install a lead flashing. If there

are open rafters then the diminish space can disappear up under the

valley into the roof void giving rats and mice a route into your loft.

Once the diminishing space drops to a height of about

300mm it would be better to stop slating or tiling and to box out the

corner with a vertical return, out to the line of the dormer fascia

board, and install a triangular infill up to the fascia board, or tilt

fillet.

With open rafters the boxing in should coincide with a

rafter position to make fixing the timber work easier. This moves the

side abutment close to the valley out to the fascia board line, making

it easier to fix the slates or tiles, and making the flashing at the

base of the valley easier to integrate into the slates or tiles. The

boxing in can either be clad in the same material as the dormer, or if

you are feeling rich, lead sheet, and incorporating the side and top

edge abutment flashings.

Vertical

Where there is a horizontal soffit board at the eaves it is possible to

take the vertical tiles or slates up to the soffit and finish with a

lead cover flashing over the nail fixings. In some instances the tiles

and slates can be fixed before the soffit is installed and the nail

fixings hidden by the soffit board, but this causes problems for fixing

the back edge of the soffit.

With open rafters finishing the tiles or slates up

between the rafters is a nightmare as the rafter centres never coincide

with the module of the tiles or slates, and short lengths of batten are

fixed to noggins, as there is nothing to fix them to above the wall

plate. If the tiles or slates can be installed before the fascia board

is installed then things are easier, but once the fascia board is

installed nailing or screwing the top three courses of tiles or slates

is almost impossible. |

|

|

The better solution with open rafters is to

install the tiles or slates as high as possible and to fix timber boards

between the rafters, on noggins fixed to the sides of the rafters, to

lap over the heads of the vertical tiles or slates and cut in under the

rafters if they come that low. The tops of the timber boards should

finish level with the top of the rafters. If low level ventilation is

needed it is possible to fix a ventilation strip along the top of the

timber board before it is installed, provided the grill does not

protrude above the upper level of the rafters. This detail avoids the

need for a lead flashing to cover the top course nail fixings.

Barge boards

A similar situation can occur where vertical tiles or slates meet the

gable ladder of the roof. Sometimes there is a wide overhang giving

plenty of room to install the additional nail fixings for the cut tiles

and slate. But often with a narrow barge board the tiles will need to be

cut around the gable ladder just behind the last rafter.

In this instance the best solution is to remove

the barge board, form a raking or Winchester cut, whichever is

appropriate, at the line of the gable ladder, and reinstall a wider

barge board to cover the last 50mm of the raking cut. If the gable

ladder is close but not tight, a soffit board screwed to the underside

of the gable ladder will be needed to stop birds and bats gaining entry

to the roof void between the vertical tiles and the bargeboard.

Conclusion

Diminishing spaces at edges and junctions are a challenge to construct,

and will require some carpentry work if it is not possible to undertake

the slating and tiling before the fascia, soffit and barge boards are

installed. Even when they are installed, fixing the ends of the soffit

boards and lead flashings can be difficult unless the junction detail is

identified and integrated at an early stage of the roofing process.

Tips

- To fix slates or tiles you need

enough room to swing a hammer or twist a screwdriver.

- Diminishing spaces up under soffits

are ideal places for birds to nest so they should be eliminated by

being designed out.

- Cutting tiles or slates in around

rafter feet where there are open rafters is difficult, and should be

designed out by using vertical boards between the rafters

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|