|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

The term lead slate refers to a vertical

pipe flashing formed in lead sheet; but whilst they are used with slates

they can also be used with tiles, provided you know how to install them.

Lead slates have been a traditional pipe flashing for

centuries. Today they are rarely manufactured on site, but bought as

preformed units, or as a metal sheet with a flexible rubber cone,

through which the vertical pipe can pass. With so many years of

experience there should be no problems associated with their

specification and installation, but unfortunately this is not the case

as I shall explain.

Head lap Most lead slates are supplied as a standard

item, they have a pre determined pitch and pipe size and come with a 450

x 450mm base sheet. This is where the problems start, as at a rafter

pitch of 35° with a plain tile or natural slate roof covering, the lead

slate can be laid within the array of slates and tiles and lap over the

lower tiles and be fully supported by 150mm, under the adjacent slates

and tiles by 150mm, and up under the slates and tiles above by 150mm.

Provided the slates or tiles are cut tightly around the pipe, that is no

greater than 150mm in diameter, it will work within the pitch and lap

requirements recommended by the Lead Sheet Association (LSA). But as

soon as the rafter pitch is reduced below 35° for natural slates,

greater lap lengths are needed and therefore the size of the base sheet

should be increased. At 22.5° rafter pitch the side laps should be a

minimum of 200mm and the head laps above and below should be 190mm,

which would require a 510 x 510mm base sheet when used with a standard

110mm soil pipe.

With interlocking tiles that can go down, in some

instances to 12.5°, the situation gets more extreme. Whilst the side lap

recommendation remains at 200mm, the head laps increase to as much as

390mm requiring a base sheet of 900+ mm x 510mm.

True pitch

The situation is further complicated by the fact that whilst the rafter

pitch may be 22.5° depending upon the size and thickness of the slate or

tile, so the true pitch of the surface of the slate or tile will be less

than the rafter pitch by between 3 and 10°. For a flat interlocking tile

like a Marley Modern the true pitch is approx 5° less that the rafter

pitch making a 22.5° rafter pitch into a 17.5° true pitch requiring a

base sheet that is 620mm long by 510mm wide.

Tile module

With interlocking tiles it is often impossible to cut a neat hole at an

angle through the centre of a tile and therefore it is often easier to

leave out a complete tile and use the flashing to fill the gap. As a

standard interlocking tile has a horizontal coverage of 300mm, and a

gauge at 22.5° of 340mm, to lap under and over the adjacent tiles by the

distances recommended by the LSA, the base sheet would need to be 770 mm

x 700mm. It is the lap of the base sheet under or over the adjacent

slates or tiles that is of importance, not the notional width of the

flashing, assuming that the slates or tile will be cut tight to the

pipe. In addition an extra 20 to 40mm should be allowed for on all four

edges for a welt, and for the distance from the head of the lower tile

to the nail holes (as the head lap should be measured from the nail

holes not the head of the tile), making the base sheet for a Marley

Modern tile laid on a rafter pitch of 22.5°, with a 110mm soil pipe, at

least 820mm x 750mm in size.

Support

Lead is unique in being unable to support its own weight. This means

that it is incapable of spanning across open space and keeping its shape

over a long period of time. This means it must always be supported. With

a double lap slate or tile this is little or no problem. |

|

|

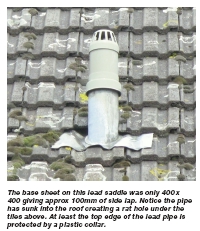

But for interlocking tiles, from the head of

the lower tile to the pipe, and from the pipe to the head of the sheet

there needs to be a timber support board at the correct level. Without a

support board the lead sinks down pulling the lead around it in further,

reducing the side and head laps. Eventually a trough forms at the base

of the pipe flashing and this fills up with debris and water and

eventually cracks and leaks. The size and shape of the support board

will vary with each tile profile and whilst it should be installed, in

normal practice it rarely is.

Collar

Where the pipe flashing passes around the pipe the top edge needs to be

sealed to prevent water running down the pipe, and down between the pipe

and the flashing. With lead it is possible to dress the top edge tightly

around the pipe, but it is still essential that the top of the pipe

flashing is either protected by a collar, or sealed off with suitable

lead compatible mastic and a stainless steel Jubilee-type clip.

Other considerations

When lead slates are installed with fibre cement slates it can be

impossible to install a copper disc rivet fixing to the slates in the

course directly above, without puncturing the lead sheet. Without the

copper disc rivet, fixing the slates will be vulnerable to wind damage.

In a similar vein the clipping of interlocking tiles to the right and

above the lead slate can be compromised as the clip needs to locate into

the side interlock above the base sheet and fix to the tile, or batten,

below the base sheet.

Conclusion

There are many situations where the only solution to weathering a

penetration through a pitched roof is the installation of a lead slate,

but there again there are alternatives for some situations which

overcome some, or all, of the problems mentioned above. These are called

ventilation tiles. In many instances lead slates are leaking not because

they are badly made, but because they were never large enough in the

first instance, or have not been installed correctly.

Tips

- Calculate the size of the base

sheet. 450 x 450mm is only suitable for steep rafter pitches. The

lower the rafter pitch the bigger the base sheet should be

regardless of the metal used.

- Always ensure that the lead

flashing is fully supported.

- The top edge of the pipe flashing

should be sealed, or covered with a collar to stop water running

down between the pipe and the flashing.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|