|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

The designers of roof tiles/slates that are

manufactured using a mould or similar process can create features that

modify and control the flow of water and wind between the tiles/slates,

which will enhance the overall performance of the roof covering. Two

such features are weather-bars and interlocks. Generally speaking,

weather bars are horizontal and interlocks are vertical, but, as is

often the case, this is not a hard and fast rule and they can be

diagonal. So what is the difference?

Weather-bars

Weather-bars are raised or depressed features on the surface of the

tile, in the head lap or side lap portion of the tile/slate, on either

the upper or lower surface. The position and shape of the features will

define their function.

Weather-bars that are moulded into the underside

of the leading edge of an interlocking tile perform two functions.

Firstly, they produce horizontal points of contact with the head of the

tile below. The greater the surface contact, the easier water travels up

the surface of the tile by capillarity between the upper and lower tile

surface.

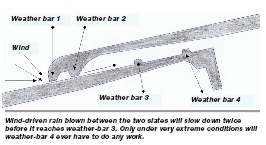

Secondly, the voids between the weather-bars reduce the

wind force blowing up between the tiles. By forcing the wind to blow

through a very small gap between the tiles (less than 1mm) into a large

void (up to 10mm high) the wind speed and force is reduced. If done two

or three times, this can reduce the wind speed down to the point where

it is unable to blow rain up the surface of the tile/slate within the

head-lap.

However, unless the weather bars run the full width of

the tile there is the risk that the wind driven rain will drive in under

areas like the interlock where there is insufficient depth to mould in a

large void behind the weather-bar. It is much easier to form features in

the underside of a tile, as this is created by the mould/pallet.

Depressions in the top surface of a tile/slate will help to attract

capillary water on the surface and may delay the onset of water tracking

down a nail hole. However, this will never be as effective at keeping

out water as an upstand on the surface, as this acts as a small wall.

Locating one upstand weather bar below the nail hole,

and one at the head of the tile, provides the maximum protection to stop

water penetrating the head lap. A weather-bar across the head of the

side interlock of a tile/slate prevents water blown up the side

interlock from draining over the head of the tile.

Unfortunately with tiles manufactured using an extruded

process, horizontal or diagonal features on the top surface are

difficult to achieve, as a smooth profile needs to be formed up the

length of the unit as it passes through the extrusion stage of

manufacture. Any depressions or upstand ribs have to be formed as a

secondary operation.

With moulded and pressed tiles, such as resin slates,

it is easy to incorporate all of the features in the top and underside

surface in one operation.

Interlocks

If the weather-bar ribs and depressions on the upper and lower surface

of the tiles/slates are designed to locate one with the other, they are

termed interlocks. Introducing interlocks with upstand ribs close to

each other will restrict the amount of shunt between the tiles.

The side interlock shunt of concrete interlocks is

maximum 6mm from full open to full close, while the variable head-lap

for a concrete interlocking tile can be up to 50mm. |

|

While there are some clay interlocking tiles

that have variable headlamps, most designs have a fixed head lap and

tend to have weather-bars that interlock. This makes the tile designs

very efficient at keeping out water, but they have to cope with the

variations in the clay from being fired in a kiln, which is not an issue

with concrete tiles or resin slate.

Vertical side interlocks also act as gutters to drain

water away, unlike horizontal weather-bars. The relative height of the

interlock with the general surface of the tile will determine the

anticipated vulnerability and water capacity of the side interlock.

The interlock of a flat concrete interlocking tile will

inevitably be below the general surface of the tiles, while a similar

design with clay pantiles will result in the interlock being at the same

level as the remainder of the tile, while some high profile tiles have

the interlock appreciably above the general surface of the tile. The

higher the interlock position, the better the performance.

Some interlocks have two channels and two ribs that

interlock, while others only have one with a larger void between them,

increasing the overall capacity of the drainage channel. The design of

the side interlock channel is critical, as the side lap distance is only

30-40mm while the head lap can be between 50mm and 125mm. It is probable

that the first mode of failure of a tile system will be through the side

interlock, before failure through the head lap.

Conclusion

Weather-bars moulded into the surface of a tile can greatly enhance the

weather resistance performance of a clay, concrete, or resin slate roof

covering. However, the method of manufacturing the tile will restrict

where the weather-bars can be installed.

Interlocks are weather-bars that locate with features

on an adjacent tile to make them interlock. Quite often, tiles of the

same profile from different manufacturers will not interlock and are

therefore not compatible.

Similarly, plastic ventilation tiles that are

sold as fitting a range of tiles may not perform as well as the tiles

they fit with, as the design of the weather-bars will be a compromise to

allow them to be fitted to a range of manufacturers’ products and

therefore will not be as tight a fit as they should be.

Tips

- Never mix tiles from different

manufacturers together.

- Never stretch the horizontal

coverage or head lap of a tile, as it may result in weatherbars

riding up on each other, causing a local stress point and breakage.

- Tiles should always lay in the same

plane to ensure the weather-bars on the underside of the tiles are

in close proximity to the tile below, allowing it to do its job

correctly.

- Depressions in the top surface of a

tile are not as effective as an upstand rib undertaking the same

function in the same locality

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|