|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

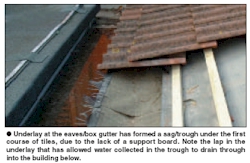

The simplest things seem to slip people's memory and yet are often the

cause of major problems at a later date. For more years than I care to

remember, all the best trade literature, specifications and roof tile

recommendations have stated, or shown, that a support for the underlay at

the eaves is essential. But I still see lots of new roofs with no adequate

eaves tilt fillets.

But why do we need an underlay support

board or fillet at the eaves?

Some of the many reasons are to collect

condensation that forms on the underside of roof tiles and prevent it

dripping back into the roof; prevent wind driven snow from being blown

into the roof and to keep the building dry until the last ridge tile is

fixed during construction. In each case the water that collects on the

underlay will want to drain down to the lowest point, which should be the

gutters, unless something prevents its progress, like a lack of an eaves

tilt fillet.

Underlay, being flexible, will follow the

line of least resistance and sag under its own weight unless it is

supported. Whilst pulling the underlay tight may sound reasonable, in

practice there is little to keep it tight. Besides, underlay stretches and

shrinks with temperature changes, creating slack.

The only way to ensure that water does not

collect in the sag of the underlay, and does run into the gutter, is to

support the underlay on a rigid timber or plywood board between the top of

the fascia board and the first tile batten for the full length of the

fascia board. On steep rafter pitches it is simple to ensure the support

board has a fall into the gutter, but on shallow rafter pitches or with

plain tiles it is more difficult and critical, especially if the underlay

is positioned below the counter batten or the fascia board height is

incorrect. If a counter batten is proposed it may be essential to place

the underlay over the counter batten rather than under it. |

|

This

needs to be checked before the first piece of underlay or counter batten is

fitted. The use of an extruded or vacuum formed

plastics support tray, either as part of an eaves ventilation system or as

a direct replacement for the support board, will provide some support. Any

plastics underlay support needs to be both deep and capable of spanning up

to 600mm to be as good as a plywood board.

The tell-tale signs of no underlay support,

or a back fall away from the fascia, at the eaves are water coming through

the soffit, especially under valleys, hips and any side laps in the

underlay. Another is to look at the condition of the junction between the

barge and fascia boards. If it is rotten or the paint is flaking

unexpectedly, it is likely that water collected on the underlay has

drained off the ends of the sag in the underlay and onto the barge-board,

making more work for the UPVC replacement fascia board and barge board

suppliers.

To blame the carpenter for not installing

the underlay support board is easy and in most cases correct, but it will

be the roofer who will always get the blame and have to put it right. It

surely makes more sense to get the carpenter to do his job properly, or

claim for extra work on the quotation for doing the correct detail, and

save your reputation. The problem may take months or years to show, but

when it does the client will want immediate retribution. Rushing the

construction of the eaves could be an expensive mistake! |

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|