|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

The UK is the main user of lead sheet in

Europe, as most countries consider it a poison. Lead is poisonous when

ingested, so all health and safety recommendations need to be complied

with when working with the material.

Lead has many qualities, the most obvious being

resistance to atmospheric corrosion. It will last for 100 years-plus

provided its installed correctly and is almost maintenance-free.

Installed incorrectly it can fail within five years (which is very

rare).

Lead is easily cut, bent and stretched, but, being

soft, needs to be fully supported, as it is not able to support its own

weight. Lead sheet is heavy, often making it difficult to lift by one

man. This weight is good at resisting wind uplift forces, but, once

lifted, it will bend easily.

Lead expands and contracts more than most metals

and, therefore, unless there are adequate laps and lengths, it will try

and move and, if restricted, result in material failure. Unless coated

with patination oil, it will oxidize and develop a white lead oxide

powder on the surface, which can stain a roof.

Overall, lead has to be treated with respect, needs

skill and time to install correctly, but is versatile. The downside is

that it can be easy to steal. So what are the alternatives?

GRP

Glass reinforced polyester has been used to form preformed lengths of

inclined valley, secret gutter and bonding gutter, which are lighter and

quicker to install than lead. Angled soakers and side abutment flashings

are also available in GRP. Like all resin made products the cost is

relative to the cost of oil. While GRP has a good life expectancy, it is

not as good as lead. However, it is more rigid and therefore, generally,

self-supporting and needs less or, in some instances, no additional

support. It has no scrap value.

Rubber

With the abundance of scrap vehicle tyres and the need to recycle the

material, there is a great potential for this material for forming

flashings. However, the available use of rubber is concentrated into

forming stepped cones to fit around pipes. The rubber is then bonded

onto other materials such as aluminium or lead, as rubber has

insufficient rigidity to resist wind uplift. It has no recycle value at

present.

Aluminium

Aluminium is light and plentiful, but it is also soft and cannot be

stretched as easily as lead. It is also not easy to weld. To make

flashings, long extruded lengths with lapped joints are used, which can

make them more difficult to fit on site. Aluminium is found in many

proprietary products, such as Flashband, a thin aluminium foil with a

sticky bitumen backing. Unfortunately, over time the bitumen leaches out

and becomes detached, making the joint look untidy. Also, the material

is restricted to set widths. Aluminium foil is also used with some ridge

and hip roll flashings in the form of a crimped material that is adhered

to a fleece such that as it stretches, the crimps unfold and allow the

rolled material to follow an undulating surface. Roof windows use

preformed aluminium flashings to form gutters around them. Provided the

aluminium is not part of a composite, it is recyclable. |

|

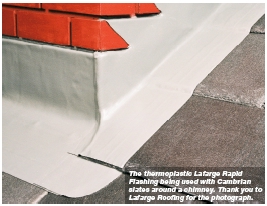

Thermoplastics

Thermo plastics such as polyethylene terephthalate and polyacetylene are

available in rolls reinforced with an aluminium expanded metal to allow

the sheet material to be stretched and maintain its new shape.

Thermoplastics soften when hot and become rigid when cold. While easy to

use, they are not self adhesive, so have to be lapped in the same way as

lead. While they are durable, they will not last as long as lead and,

being composite, are not recyclable, and therefore have no scrap value.

Zinc

Zinc was used for many years as a cheap alternative to lead for inclined

valleys. Being relatively brittle and susceptible to environmental

decay, it was not seen as a long-term solution. It is often used as a

coating on other metals, such as steel and aluminium, making them

corrosion resistant. Zinc is recyclable and not poisonous, so seen as

more environmentally friendly than other metals.

Stainless Steel

While stainless steel is expensive, it has been used to form inclined

valleys and other simple cappings. It is very corrosion resistant, long

lasting and recyclable. But, being very rigid, it is impossible to form

into complicated shapes on site.

Conclusion

There is no one material that can perform better, or for longer, than

lead for roof flashings. Other materials can emulate lead in certain

situations, and they need to be understood and used within their

capabilities. Pure materials such as aluminium and zinc can be recycled

provided they are not part of a matrix and are recyclable, but it

makes them vulnerable to vandalism. Products that contain oil-based

materials are subject to the price of oil. Plastics should only be used

where they can demonstrate resistance to ultraviolet light and can be

easily replaced at a later date when they fail, which they will, long

before the tiles or slates.

Tips

- Avoid plastic-based materials in

locations that would be difficult to change at a later date, such as

an inclined valley or a change of pitch in a slate mansard roof.

- Select a flashing material that will

last as long as the roof covering it is being used with.

- Lightweight materials may be easier

to install, but unless they have additional fixings, will be easier

for the wind to rip off.

- In future, all materials will need

to be recyclable; therefore, certain composite materials may become

environmentally unfriendly, regardless of their performance in use.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|