|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

There are particular roofing issues that relate to the installation of

chimney and dormer window units that need to be taken into

consideration. In this first section we shall look at the construction

up to tiling/slating the roof around the chimney/dormer window unit.

Design and construction

The position of the chimney/ dormer window unit should be determined

early in the design process to suit the layout of the room, or to

simplify the layout of the trussed rafter units. But consideration

should also be given to the module of the tiles/slates and the distance

from other features such as other chimney/dormer window units, the side

abutment, or verge.

Careful sizing and positioning can increase the security of the

roof and reduce the installation cost.

In the majority of situations the chimney/dormer

window units will be fixed to a timber trussed rafter, or attic truss

roof construction, although they are suitable for other constructions

like composite panels.

The opening width and length are predetermined by the

size of the units and the pitch of the roof, and should always be

trimmed top and bottom. Depending upon the weight of the units they

should also have a double rafter under the vertical wall faces, and

additional rafters and trimmers under the outer edges that form the side

and head flashings.

If the trimmers and additional rafters are missing, it

will be difficult to finish the underlay and battens around the

chimney/dormer window unit, and may result in long-term deformation of

the unit.

The additional rafters under the side flashings should

be positioned to allow the ends of the battens to be nailed to the

additional rafter. This may require a 50mm x 50mm batten nailed to the

side of the additional rafter to provide sufficient width to support and

nail the ends of the battens.

Underlay and battens

Across the bottom and up the sides of the units the underlay should be

fixed to the rafters before the unit is fixed into position. But at the

head, the underlay should lap onto the edge of the back gutter or

inclined valley, depending upon the design of the unit.

If the underlay laps onto the side flashings there is a risk of

water tracking between the underlay and the side flashing and dripping

into the roof. At the head, if the underlay laps under the back gutter

or inclined valley, any water on the underlay will run down between the

underlay and the unit and drain inside the roof. Often the

chimney/dormer window units are installed before the roof covering has

been started. It is best done in collaboration with the roofer.

The battens should be gauged out using the head and

tail of the units as fixed points. Depending upon the tile/slate module,

and the size of the units, a short course of tiles/slates may be

required. The side flashings and back gutter/ inclined valley are

designed to sit on the top surface of the rafters and can be up to 10mm

thick. The battens should be cut up to the edge of the side flashings

and fixed into the additional rafters to ensure there is a secure fixing

and should not be lapped onto the side flashing as this will cause the

edge tiles/slates to kick up.

Flashings

Some units have the apron flashing built in, while others have to be

installed separately. Regardless of which situation applies, the

flashing should be long enough to lap over the lower course of

tiles/slates. In many instances the flashing is just capable of

achieving 150mm of lap onto a slate that is butted up to the unit

framing, but is not long enough where the gauging-out results in a gap

between the head of the tile/slate and the chimney/ dormer window

framing, or where high-profile Roman or Pantiles are used, as the

flashing has to rise up to the height of the corrugation, reducing the

lap length. |

|

Where the rafter pitch is less than 35º the length of

the flashing should be increased in accordance with the recommendations

of the Lead Sheet Association.

The flashing should either lap under the chimney/dormer

window unit by a minimum of 150mm, or, if the distance is less, turn up

to form a 50mm high vertical step within the unit construction. Where

the apron flashing extends under the side flashing it is not possible to

form a 50mm upstand, so the alternative has to be used. At this point

the apron flashing will be unsupported, so a timber support board should

be installed between the main rafter and the additional rafter, and to

the end of the flashing if it extends beyond the additional rafter.

At the junction between the upstand and the side

flashing, the apron flashing should not be cut, as that will form a leak

path. The flashing should be bossed, or a section welded in. Where the

flashing is dressed onto the head of the tiles it is common for the

flashing to form a trough between the framing and the tiles, which in

some cases is up to 100mm higher above the rafter face. Water that is

trapped in the trough can run sideways and under the first course of

tiles on either side. At this point there should be a welt to stop the

water flowing off the end onto the underlay. It is better to have no

trough there in the first place.

With profiled tiles the flashing should be dressed down

into each corrugation to allow the first tile on each side to sit

correctly into the tile below, without being kicked up.

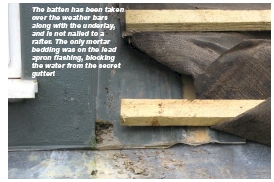

Back gutter

Where there is a back gutter arrangement there is often no tilt fillet,

or one of the wrong height. Each type of tile/slate will require a

different height of tilt fillet. Placing a loose timber batten on the

back gutter is not correct as it will be affected by water over time.

Mortar bedding the first row of tiles/slates will also

be incorrect as it will restrict any water on the underlay escaping. The

correct detail would be for the correct height of tilt fillet moulded

into the back gutter, or for a minimal tilt fillet moulded in with a

plastic ventilation grill of the right thickness, nailed into position.

Conclusion

Unless the basic construction, underlay, and battening is correct, what

follows will be uneven and insecure. The apron flashing and back gutter

detailing are also very important – water could seep into the building,

or, over time the construction will deteriorate. Part two will deal with

installing the roof covering around the chimney/ dormer window unit.

Tips

- All edges of the chimney/dormer

window unit should be fully supported and provision left for the

ends of the battens to be fixed to the additional rafters.

- The apron flashing should be long

enough to provide a minimum 150mm lap, avoiding the formation of a

trough that will collect water and discharge it sideways under the

adjacent tiling.

- The tiles/slates above the

chimney/dormer window unit should sit on a tilt fillet of the

correct height

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|