|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

In most cases, slates or tiles are either put onto new buildings or they

are used to re-roof an old roof; either way, all new battens will be

used.

But there are instances where the roof may be fairly

new and repairs need to be undertaken that do not warrant the total

re-battening of the roof, but require the battens to be cut, repaired or

refixed. Where the roof structure is constructed from timber trussed

rafters, the repair needs to be undertaken very carefully to maintain

the integrity of the roof structure.

Single batten

replacement

BS5534 and BS8000 Part 6 state that no batten should be less than 1.2m

long, such that at 600mm centres the batten will rest on at least three

rafters. Battens that only span between two rafters are more likely to

sag than those that go over a central support (hogging moment).

Where the batten goes over a rafter, there is

tension in the top fibres, while there is tension in the bottom fibres

between the rafters. One helps to cancel out the other and keep the

battens reasonably straight. If the end of the batten rests on a rafter

(end bearing) there is no hogging moment, and so the batten is more

likely to sag under load.

If an isolated batten between two rafters has to

be cut out and replaced, it is better to either cut out and replace the

batten over three rafters, or to install an additional batten of the

same size below the short section of batten. The lower batten should be

long enough to span over – and be nail fixed to – four rafters. The

short and long battens should also be nailed to each other.

Multiple batten

replacement

BS5268 requires that battens

should be joined on the centre line of a rafter, and with trussed

rafters, no more than one in any group of four consecutive battens

should be joined on the same rafter. For tiles and slates where the

batten gauge is less than 200mm, no more than four in 12 consecutive

battens should be joined on the same rafter.

If more than one batten has to be replaced,

the batten joints should be staggered. The reason for this is that the

battens provide the lateral restraint for the timber trussed rafters,

and any group of consecutive joints in the battening will affect the

rigidity of the structure.

For interlocking tiles, this means that either

the battens need to span over five rafters and be staggered (meaning

that an area of roof up to 4.2m wide may be affected), or an additional

batten long enough to span over two additional rafters must be installed

below the existing section of batten that has been reinstated, and the

additional batten must be nailed to the rafters, and to the replaced

section of batten.

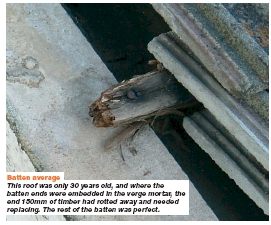

Verge or side abutment

Where the battens end at a verge

or side abutment, and are either rotten because they have been embedded

in the verge mortar, or need to be lengthened to allow for the correct

installation of a dry verge system or gable wall cladding, the rotten or

affected battens should be cut back and staggered, to make sure only one

in any group of four consecutive battens join on one rafter. |

|

This means that the shortest batten will be

about 1.5m long and the longest approximately 3.3m long where the

rafters are at 600mm centres.

The alternative is to install an additional

batten of the same size (and approximately 1.5m long) directly below the

replaced end section of batten, and twice nail the short end section to

the additional batten, then also nail the additional batten to each

rafter and the existing batten for maximum rigidity.

Mid span support

Where a batten is cut between two

rafters to accommodate a pipe or flue, and the end of the batten is

unsupported, a short length of batten approximately equal to three times

the batten gauge should be slid up under the unsupported end of the

batten and screwed to the unsupported batten and the battens above and

below.

Batten joints

Battens should always be joined

at a rafter. The ends of the battens should be square cut and tightly

butted to the adjacent section of batten and skew nailed into the

rafter, to prevent the batten end from splitting.

With timber trussed rafter, this may result in an

end bearing of less than 17mm. Therefore, it may be better to cut the

batten in line with the side of the rafter and install an additional

38mm x 38mm timber noggin onto the side of the rafter flush with the top

of the rafter, to allow the new section of batten to be nailed to it.

This is easier said than done, as the noggin should be below the

underlay, while the batten is above it. This is normally only possible

where the underlay is also cut through for access.

General

Where repairs are being undertaken, new battens of the same size should

always be used. Edge fixing into battens thinner than 25mm thick is not

advisable as the nail-to-edge distance will be very small and can split

the batten, taking away any strength that may have existed. Where the

battens are cut out or modified, the resulting repair needs to maintain

– or improve – the integrity of the roof.

Tips

- Knotty, rotten or split battens have little or no strength and

should be cut out and replaced.

- Where battens are joined at a

rafter, increase the end bearing by nailing a 38mm x 38mm batten to

the side of the rafter.

- Unsupported ends of battens can be

supported with a vertical batten screwed to the battens above and

below.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|