|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

In

part one of this subject we looked at the purpose of tile clips, and

their various types, materials and constraints. In part two we will

concentrate on the fixing of the tile clips.

Fitting

Fitting most tile-to-tile clips and batten hook clips is simple as they

do not require any form of tool to fit them. Most are plastic or spring

wire and have a push-fit spring action that locks them into place. They

normally locate into the interlock first, and then are slid down the

interlock until they locate against the head of the lower tile, with one

leg under the lower tile or the timber batten. If the two tiles are not

lying in the same plane – possibly because the fascia board height is

wrong – then the clips will not fit correctly.

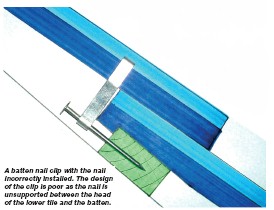

Batten nail clips require some form of barb or nail to

be driven into the timber batten. This is easy if you are left-handed,

but more awkward if you are right-handed, as the clip is always on the

left hand side of the tile (looking from the eaves).

Most clip nails are unsupported between the clip and the

batten; a distance that can vary from 8mm to 55mm, depending on the size

and location of the nibs. Some clip designs are L-shaped and support the

nail, making them act as a tileto- tile clip, as well as a batten nail

clip. Supporting the nail also helps to ensure the nail goes into the

centre of the batten (useful when you cannot see the batten you are

nailing into), and stops it bending under load, making the clip much

stronger.

All clip nails should be driven in fully so that the head of the nail is

hard against the clip. This is often difficult to do as the nail can

bend before the head reaches the clip edge. The greater the distance the

nail head is off the clip face, and the greater the length of

unsupported nail, the weaker the tile clip fixing will be. Under load,

the clip will be pulled up the nail and out of position. The unsupported

nail will bend, allowing the clip to disengage from the side interlock.

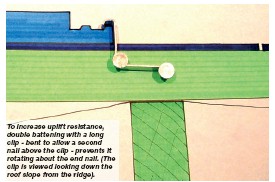

To increase the security of some clip fixings, it is possible

to double batten and use two nail fixings to hold the clip. The second

batten should be 38mm x 38mm and be placed against the head of the lower

tile, and nailed into the rafters with 80mm-long nails. The tile should

be located into position, and the clip, which should have a horizontal

leg, should be nailed into position in the normal manner. A second nail

is then installed above the clip and into the centre of the vertical

face of the second batten to stop the clip rotating about the first nail

fixing, so holding the tile down tightly. This type of clip fixing can

be very effective for Redland Stonewold Mk II and Delta tiles, which

normally have a plastic batten hook fixing.

Instructions

Very few tile clips come with fixing instructions in the packets,

therefore fitting them comes with practice and experience.

Identification of the clips can also be difficult. |

|

|

While some manufacturers mark the clips with

the tile model name, others have a number or letter code, which if you

are not familiar with, can make identification difficult. Some

manufacturers sell the clips separate to the nails, making the risk of

using the wrong nail even greater.

Maintenance

To check that a tile is nailed, the technique is to try and push the

tile up the roof slope (usually with one’s boot). If it does not move,

then it is likely to be nailed, but may also be clipped. If when sliding

a trowel under the leading edge of the tile and lifting the tile it will

not lift, then the tile is clipped.

It is possible to remove a tile clip by pushing the

tile below the clip up the slope (again with one’s boot). This will pull

the nail out of the batten. If the tiles are clipped with tile-to-tile

clips, a slate ripper may be needed to push the clip off the head of the

lower tile. With batten hook clips, the section that hooks into the

interlock may need to be released first.

Reinstalling the clips can be impossible or at least

very difficult. The best technique is to relocate the clip into the

batten – or onto the lower tile – and hold the interlock hook section of

the clip up with the end of a trowel, and slide the tile interlock in

under the clip, before releasing the clip. The alternative is to drill

through the leading edge of the tile, above the nail hole of the tile

below, and screw through into the batten below, ensuring that the hole

is protected with a neoprene washer and cap.

Conclusion

In sheltered locations, interlocking tiles may not need clipping;

nailing will be adequate. In most moderate locations, tiles that are

clipped will resist the anticipated winds that will occur in that

location. In severe locations, some clips will be inadequate and will

require either a more secure fixing or an alternative tile with a better

clip design.

Finding out which clips are the strongest is not easy

to discover, and often requires discussions with the tile manufacturer’s

technical staff, as this information is rarely published. Alternatively,

a full fixing specification should be obtained from the manufacturer.

Plastic clips are easy to use and easy to fit but will

never last as long as the tiles, and will become brittle, with unknown

consequences. Spring wire clips are easy to install but are unlikely to

stop tiles chattering, unless they are very tight-fitting. Identifying

clipped tiles is simple; removing and replacing them is not so easy and

is best kept to a minimum.

Tips

- Always get a fixing specification

from the tile manufacturer, and follow it.

- Always drive the nail down onto the

clip face for batten nail clips.

- Try to drive the clip nail into the

centre of the 25mm face of the batten.

- If a batten hook fixing coincides

with a rafter, find an alternative clip rather than just leaving the

clip out.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774

|

|