|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

It is the little things that make all the

difference in our lives. They are the things that are difficult to see

and are therefore easy to forget, and the untrained eye is not aware of

their existence, or importance. For interlocking roof tiles, the

important little things are the tile clips.

With interlocking tiles, there are three main types of

clip: eaves clips for eaves tiles; verge clips for verge tiles; and tile

clips for every other tile on the roof. This first article will not be

dealing with the eaves and verge clips, although many of the issues

covered will be the same as for tile clips.

Purpose

Tile clips are the most efficient method of preventing interlocking roof

tiles from being sucked off of a roof by hurricane force winds, and they

should also help to prevent tiles from chattering at lower wind speeds,

(but that may vary from one clip design to another).

Each design of tile clip will have a slightly different

performance figure with each design of tile. The performance is called

wind uplift resistance and is measured in Newtons (N). In very general

terms, a tile’s uplift resistance is the sum of its dead weight

resistance plus the resistance of the fixings.

The dead weight of a tile will resist (depending upon

the rafter pitch) approximately 1,000N of wind suction force. One head

nail fixing will provide approximately 500N resistance, while a well

designed clip could add between 2,000N and 6,000N resistance; making

clip fixings between four and 12 times better than a single head nail

fixing. Designs

Almost every design of interlocking tile will have a clip specifically

designed and made for it. Some are good and some are not so good, but

regardless, there is almost no alternative tile clip for each roof tile.

Most roof tile manufacturers have tried to design a

universal tile clip, but so far nobody has succeeded. Some clips will

fit a few tiles that are similar, but nobody has ever made a clip that

works adequately for all interlocking roof tiles, whatever they may

claim.

There are three basic designs of tile clip:

tile-to-tile clips; batten nail clips; and batten hook clips. Some clips

have features that make them both batten nail and tile-to-tile, or

batten hook and tile-to-tile, but nobody has ever produced a clip that

could be classified in all three categories.

Tile clips are also manufactured from a range of materials,

from aluminium and stainless steel to plastic. Galvanised steel clips

are popular in dry countries like Australia, but would not last long in

our climate. Of the metal clips, most are manufactured from strip or

sheet material, while some are made from spring wire.

The rigidity of some sheet metal clips can resist

uplift loads with little or no movement of the tiles. This is good as it

prevents the tiles from lifting and rattling. However, those made with

spring wire have a varying rate of resistance: the greater the suction,

the more the tiles lift, the more the clip bends and the greater the

resistance force.

Therefore, a spring wire clip will allow the tile to

lift before the maximum resistance value is achieved; then the spring

forces the tile back into position, which may cause tile breakage.

Spring type clips are not ideal for single pantiles, as the spring pulls

the left-hand side of the tile down and out of its normal laying

position.

Plastic clips are the most complicated to look at, but often the

easiest to install, as injection moulded plastic allows the designer to

include stiffening ribs and features that would be impossible to

reproduce in any other material. |

|

|

In contrast, metal clips have to be punched

and bent to shape, and are therefore limited by the production process.

They can also be bent onsite to fit, if needs be.

Design constraints

To perform its function, the tile clip has to hold the tail of the tile

down by fitting into the left-hand interlock, pass down the head of the

lower tile, and either lock under the head of the lower tile

(tile-to-tile clip), or allow a nail to be passed through the clip into

the narrow face of the batten (batten nail clip), or pass around the

underside of the batten, so that any upward movement of the tile will

cause the clip to grip the batten (batten hook clip).

The end of the clip that locates into the side

interlock must be as thin as possible and shaped to suit the shape and

size of the interlock edge, to ensure it does not interfere with the

tile above. The portion of the clip that passes down the top edge of the

lower tile needs to be as vertical as possible, to give a straight pull.

The greater the horizontal distance from the interlock to the nail

fixing, the less effective the clip will be. The distance from the top

of the interlock to the underside of the tile below is critical for

tile-to-tile clips, and to the underside of the batten for the batten

hook clips and batten nail clips. Generally, flat tiles have a shorter

distance to the top of the batten than profiled tiles.

Once below the top face of the lower tile, the clip must not

interfere or clash with the tile nib, especially if the clip is nailed

to the batten. This can become a problem with some flat tiles when the

perpendicular joints drift out of alignment. Where tile-to-tile clips

are used, the lower tile should be head nailed to transfer the wind

uplift force from the clip, via the tile, to the batten below.

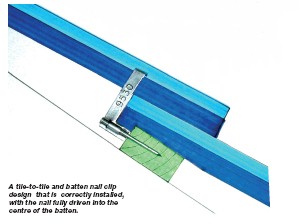

Where the tile clip is nailed to the batten, the nail should be

driven into the centre of the narrow batten face. With a 25mm-thick

batten, the distance to either edge will be, on average, 11mm. While

this is 4mm less than the minimum recommended by BS5268, it has been

found over many years not to be a problem and, therefore, is acceptable.

However, if the nail fixing is into a 19mm batten, or is off centre of

the 25mm batten, then the distance of the nail fixing to the edge of the

batten will be less than 11mm, and the risk of splitting the timber is

higher. Once the batten splits, the grip of the nail will be affected,

along with the resistance value of the tile clip.

Batten hook clips are mostly designed to fit

specific batten sizes, and may be a slack fit for smaller batten sizes,

or may not work at all if the batten is too large. Often the clip

position will clash with the rafter or counter batten position and make

it impossible or difficult to fit the clip.

Tips

- Always use the tile clip recommended

by the tile manufacturer.

- Metal clips are generally stronger

and will last longer than plastic clips.

- All tile clip designs have a better

uplift resistance than head nail fixings.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|