|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

The supply and use of mastic is one of

the great growth sectors of the pitched roofing industry. There are so

many manufacturers selling a wide range of tube and bead mastics and

sealants, there must be a lot of money to be made. But which should be

used with slates, and where, and why?

Perhaps the safest answer is that a good roof

should be constructed using no mastics at all. We managed to construct

roofs perfectly well before they were introduced, so why are they used?

Convenience is the answer. There is nothing that

so universally fixes anything that is broken than mastic. But is that a

good thing? Like anything that is good, it can be abused and used for

the wrong purpose.

Natural slate

If I look at a slate roof and see slate that is out of alignment, or has

a nail pushed in under the leading edge, it is almost certain that that

slate is held in with some form of mastic. If you need to replace a

slate in a roof, it can be a big job to strip down from the ridge and

replace the slate properly.

Copper tingles will allow a temporary repair of an isolated

slate but are clearly visible from the ground; a thing no roofer wishes

to admit to with a new roof.

Remedial repair clips, like Owen’s Jenny Twins,

are effective and hidden, but not easy to obtain at short notice, and

require some practise to install correctly. So mastic it is!

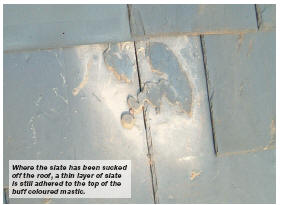

Unfortunately, with natural slates there is one

big problem with any form of mastic: regardless of how well the mastic

or sealant sticks and bonds to slate, being a laminar stone, slate is

made up of layers of sediment bonded together by heat and pressure; this

is what makes it possible to split it into thin sections. But,

unfortunately, the mastic is only bonding with the outer-most layer of

the material, and if you pull on the bond, the outer layer of the slates

pulls away, leaving the mastic with a thin sliver of slate on the

surface.

Fibre cement slate

But, I hear you say, what about fibre cement slates and resin slates

that are not laminar stone? The act of applying the mastic to the

surface of either the front or back of a double-lap fibre cement slate

is likely to alter the capillary line of water sucked up between the

slates when it rains.

Having a surface that a meniscus of water can

adhere to, it will creep further under the slate than normal. The common

s-shaped squiggle or central blob of mastic gives the water a route to

reach the nail holes, or the top of the headlap, where it drains down

the nail holes or over the headlap onto the underlay, and worse still,

can be trapped in a pocket and freeze, blowing the two slates apart.

Single lap resin slate

With single-lap resin slates, one manufacturer sells a repair kit that

uses PIB (polybutileisolene) bead strips (which is the material that car

windscreens are glued in with) to glue the new tile back into position.

What makes this work is that resin is a known quantity

once the surface silicone release agent has been cleaned off, and the

instructions that come with the material point to where the material

should be adhered to allow the slates to keep water out at all times. If

used incorrectly, the water-shedding properties are affected.

Site conditions

Many mastic materials work perfectly well between certain temperatures,

levels of humidity, onto clean dust and oil-free surfaces. |

|

|

But, unfortunately, building sites and roofs

are not ideal places to apply some materials. Invariably it will be

raining, or has just stopped raining; the temperature of the roof will

be ice cold or hot enough to fry an egg; and the slates covered with

dust, dirt, diesel fumes and hand prints: not an ideal environment to

apply any mastic. Life

expectancy

Regardless of the type of mastic/sealant, be it silicone, polysulphide,

synthetic resin, polybutileisolene, or any other material, its life

expectancy will never be as good as the slates or lead flashings that

they are trying to adhere to.

Also, the bond strength of the material may be

excellent when it is first applied, but after a few years it will begin

to lose its properties and shrink, crack, discolour, harden and weaken;

but not all at the same time. Some materials will do these things

quicker than others, and generally, the more expensive the material, the

longer it will last; but nothing lasts for ever.

Noise

There are some very good reasons to use mastic on a slate roof. The

first is where some of the slates are a little gappy and rattle in the

wind. By placing a small dob of clear silicone mastic under the two

outside corners of the slate, it acts as a shock absorber and stops the

slate rattling.

Flashings

The second situation is the fixing of lead flashings into a brick joint.

Lead expands and contracts more than most materials and can cause mortar

pointing to break up.

The use of the lead pointing sealant will cope

with the situation far better than mortar. But the material is not

designed to glue lead flashings to slates in place of lead clips. It is

not designed to fill splits in lead both old and new, and it is not

designed to repair broken slates.

Water seal

The third situation is where an end ridge tile is screw-fixed to the

roof structure and the screw and screw-hole need protecting. Filling the

nail hole with silicone mastic and covering the screw head to form a

water proof dome is acceptable, provided you do not want to dismantle it

in the near future.

In conclusion

Like all good things, mastic and sealants should be used sparingly, at

the right time, and in the right place, and they will enhance a good

slate roof; but if not used correctly, can spoil a perfectly good roof.

Tips

- Think twice before using any form of

mastic.

- Read the instructions and conditions

of use data sheet before using the material, to ensure that it

applies to your situation. If it is not listed, do not assume it

will work because it is not listed as not working.

- Never use mastic to glue natural

slates together.

- Never use mastic in very hot or very

cold temperatures.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|