|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

In part one of this subject we discussed the

design implications of roof windows. In part two we look at the

installation of roof window flashings.

Narrow cuts

The installation of the roof window is always a problem as it is

normally the carpenter who installs the window to suit the rafter

spacing and the sill/head dimensions provided by the designer to satisfy

the Building Regulations, before the roof is tiled or slated.

The size of the window is normally chosen to

accommodate a particular thermal, light, or means of escape requirement,

with no consideration for the module or setting out of the roof

covering. Consequently, the fitting of the tiles or slates around the

roof window can result in narrow cuts down the sides of the roof window,

insufficient lap at the back gutter, and a trough between the bottom of

the window frame and the head of the course of tiles under the apron

flashing.

On the continent, the roof windows are normally

installed by the roofer after the roof has been tiled, or during the

roofing process, to allow the window to be positioned to suit the roof

covering, not the other way around.

Kicking up

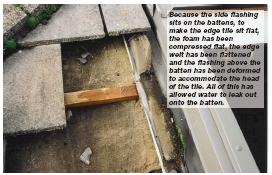

Narrow cuts at the side channels will cause problems in fixing as the

side channel flashings lay on the battens; therefore, to nail a narrow

cut to the batten often results in the nail puncturing the side

flashing. Additionally, because the side flashings lay on the battens,

it lifts the edge tile by more than the thickness of the flashings. The

head of the tile is lower than the nib position when laid, as the tiles

lay at approx 50 less than the rafter pitch, and it prevents the tile

nib from locating onto the batten, especially if the nib is continuous

across the head of the tile.

In trying to get the edge tiles to sit without

kicking up too much, the nib is often removed, the edge welt on the

flashing is flattened, making it ineffective, and the top tiles that

kick up disturb the tiles on the course that runs through above the back

gutter. The gapping that is generated between the tiles, especially

where slates or tiles are laid broken bond, can allow wind-driven rain

to get in through the gaps, beyond the edge of the flashing.

Tilt fillet and underlay

The tiles that rest on the back gutter often lay at the wrong angle as

there is often no adequate tilt fillet to support them at the correct

height. Each tile design will need a different support height to

accommodate the tile body thickness and weather-bar arrangement.

Where the tiles have to be all clipped – or clipped

around the roof window – a standard clip is impossible to fix without

penetrating the flashing/underlay. The only easy method is to use a

verge clip laid vertically and nailed to a secondary batten. The use of

a piece of tile batten laid in the back gutter to support the edge tiles

or slates is unsatisfactory, as the timber will get wet and rot away

prematurely, or slide out. |

|

There is a requirement to turn the underlay

up the sides of the roof window by approx 50mm to ensure any water on

the underlay does not leak in under the window frame. Unfortunately, at

the corners (unless the side pieces of underlay are separate from those

above, and below the roof window) there will be holes in the underlay at

each corner. The common practice is to mitre cut the underlay at the

corners to let it turn up, leaving a V shaped hole at the corner that

can let water drain in.

Leaks at the corners would indicate that there are

problems with the flashings around the window or higher up, as without

the water draining through the hole on the corner, the underlay would

act for many years as the primary waterproofing layer and rot through

long after the guarantee on the roof window had run out.

Some companies provide a gasket that is

laid over the battens before the flashings are fitted, which lifts up

the side flashing by the thickness of the gasket. The gasket sticks to

the battens and underlay, to protect the four corners of the roof window

and disguise the fact that there is any water leaking onto the underlay

through the tiles or flashings.

Debris traps

Around the roof window flashings, there are potential traps where

leaves, pine needles, moss, snow and other natural debris can collect

and prevent rainwater getting away, leaving a problem, especially with

windows installed in shallow pitched roofs. The heavy metal roof

windows, with plate hinges and bolts that extend into the back gutter,

can collect debris between the two hinges.

At the bottom of the side channels, the

flashing has to change pitch to rise up onto the top surface of the

tiles in the course below the roof window. Where this change of pitch

occurs, it forms a dip that allows debris to collect and obstruct the

water flowing down the side channels.

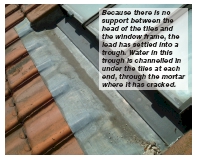

A shallow trough can occur where the apron

flashing spans from the frame to the top of the tiles in the course

below the window. This can collect debris and channel water sideways

under the tiles on the first course on either side of the window and

onto the underlay.

In conclusion

Roof window installations with proprietary flashings are an easy fixing

option. They are a Jack-of-all-trades and often a master of none.

Purpose-made lead flashings, correctly installed, to the correct width

and laps, would be a much better option for most situations, but would

be more work and less convenient. In many instances, the roof windows

are excellent, but are let down by the poor performance of the integral

or removable flashings.

Tips

- Do not cut the underlay at the

corners of the window frame, but use separate pieces lapped onto the

one below.

- Try and choose a window sized and

positioned to suit the module of the tiles or slates, to eliminate

all narrow cuts.

- Use verge clips to secure edge tiles

where the normal fixing would penetrate the flashing and compromise

the weather resistance.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|