|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Ridge construction part 3 looks at ridge

fittings and accessories.

Fittings and accessories

Fittings are items like ridge tiles that are made in the same

material as the roof tiles. Accessories are made of plastic, metal or

another material that make up a system such as dry-fix or ventilation

components at the ridge, or ridge terminals. In some instances fittings

and accessories are fixed together, while on others they are not. The

compatibility of fittings with accessories varies enormously, even when

they are sold as universal products, and should be checked with the

manufacturer of both components that are being put together. The

ultimate responsibility for their compatibility is the specifier.

Ridge fixings

Ridges that are not mortar-bedded must be secured against wind uplift by

some other means. For ridge tiles this means nails, screws, straps or

clips that are secured to a ridge board, secure ridge batten or a patent

edge channel. Most clay and concrete ridge tiles are secured along the

centre line of the ridge directly above the apex of the roof, either

through the ridge tiles or through the joints between the ridge tiles

with plates or straps. Fibre cement ridge tiles tend to be screwed along

the outside edges into the top battens on each roof slope. This works

well provided there is no flexing or movement in the roof structure,

which can result in the ridge tiles cracking along the apex. This can be

partially compensated for by drilling oversized holes for the screws.

But as the amount of movement only becomes evident after a few years it

is easy to get wrong.

Metal ridge systems, such as preformed zinc and lead

rolls, rely upon being nailed to a ridge batten of the correct height

and size. In exposed locations galvanized metal straps positioned on the

laps, and screwed into the batten below, may be needed.

The number and spacing of the nails, screws, clips or

straps will depend upon the system being used. Ridge tiles up to 500mm

long will require at least two annular ring shank nails (minimum 3.7mm

diameter), and penetrating the ridge batten by a minimum of 35mm, or one

screw 5mm diameter (no 10) penetrating the ridge batten by a minimum of

35mm. Smooth nails are not suitable as the grip of the nail into the

timber is insufficient to prevent them withdrawing.

For longer ridge systems, or when using proprietary

clips, the manufacturer should supply recommendations and fixing

instructions.

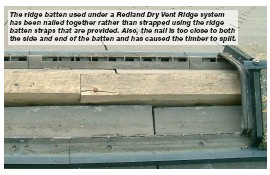

Ridge battens

What the ridge tiles are fixed to must be sufficiently strong, and

securely fixed to transfer the wind uplift loads back into the roof

structure. Therefore, the ridge batten should be at least 38mm deep and

11 times wider than the nail diameter, or seven times the screw

diameter. The screws or nails should be fixed as close to the centre of

the batten as possible, as a nail close to the edge can cause the timber

to split. The recommended distances quoted in BS 5268 part 2 are: five

times the diameter of the nail in from the edge of the timber and 20

times the diameter in from the end of the batten.

Nails require ever-increasing impact loads to drive

them into the timber, which will try to deflect the impact load.

Therefore, the ridge batten needs to be as rigid as possible. Laminating

three or four layers of tile batten together is insufficient if there is

no ridge board underneath it, as the individual pieces of timber will

act like a leaf spring spanning between the trussed rafters. If the

batten deflects under the nail-driving impact load, it is possible to

reach a point where you cannot continue to drive the nail into the

timber as greater impact loads just cause the ridge batten to deflect

more and more. As the ridge batten deflects it causes the nail head to

go down relative to the ridge tiles, and come back up again and remain

slack.When screws are being installed they require an ever-increasing

turning load which is pulling the ridge batten up – taking slack out of

it. |

|

|

Therefore, it is possible to use a smaller

section of timber as a ridge batten as deflection is not an issue. Also

the screw can always be pulled down onto the ridge tile or plate without

leaving it slack. Sections of ridge batten may have to be removed to

allow pipes or flues to connect to ridge ventilation terminals or flues.

They should not occur in adjacent rafter spacings, as the ridge batten

must be secured to at least two rafters.

Ridge batten fixings

The fixing of the ridge batten to the timber or metal roof structure is

also critical, and it is important that the extreme forces at the ridge

do not pull the fixing out. A ridge board with additional battens fixed

above it, to give it additional height, should be fixed using ridge

batten straps or a long screw at 600mm centres (maximum) to hold them

together. Skew nailing into the ridge board is also possible if the

ridge board is wide enough to hold the nails, but on older roofs this

may not be appropriate.

With trussed rafters it is not possible to nail into

the apex of the truss as this is a dry-mitred joint and will not hold a

fixing. To prevent the timber splitting, the nail or screw fixing needs

to be at least 20 times the diameter of the nail fixing away from the

apex. Nails perform much better in shear than withdrawal, so where

possible the nail should be driven in at right angles to the vertical

upward pull of the ridge under wind load.

If ridge batten straps are being used they should be

either twisted and nailed to the face of the trussed rafter, or bent

down the top face of the rafter under the top batten position. It is

essential to drive an annular ring shank nail, or a screw, into the top

of the rafter through the fold in the ridge batten strap to take all the

slack out of the strap fixing.

Over a year the timber (or steel) roof will move with

thermal and moisture expansion and contraction. This can cause the ridge

of a domestic roof to rise and fall approximately 40mm. This movement

can pull a bent strap straight and result in the ridge batten rising off

the apex of the trussed rafter. This can produce what is known as

‘rising nail syndrome’, which only happens at the ridge.

Weather resistance

The position of waterproofing membrane under the ridge tiles, or the

ridge to ridge seals, and skirts between the ridge tiles and the roof

tile/slates, will vary, and the fixing instructions should always be

followed. The majority of waterproof membranes should be installed over

the ridge batten to protect it. With systems without a waterproof

membrane the ridge batten does not need additional protection. Skirts

and waterproofing membranes should be long enough to lap the head of the

roof tiles and slates on each roof slope by a minimum of 75mm to protect

the head nail holes. This may be difficult for deep profile tiles such

as clay pantiles or unders and overs, and may require the skirt material

to be able to stretch up to three times its original width, and

one-and-a-half times its length. The steeper the rafter pitch, the

narrower and deeper the corrugation, the more critical the skirt

material stretch will be.

Tips

- Install any ridge battens before

installing the top tile/slate battens.

- Nailed ridge tiles should be fixed

to a solid timber, rather than laminated tile battens, onto timber

trussed rafters.

- Ridge battens should be strapped

down with no slack to trussed rafters to prevent slack nails at a

later date.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|