|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Ridge construction part 2 looks at the roof

structure and the installation of the ridge tiles, with special

reference to mortar bedding.

Roof structure

With a traditional cut timber roof the apex of the roof

structure is a ridge board against which each timber rafter is set and

fixed. The rafters on one roof slope should line up with the rafters on

the adjacent roof slope. The width and height of the ridge board will

vary from roof to roof. With a trussed rafter roof there is no ridge

board and the rafters are mitred together at a point making it easier to

position the top batten closer to the apex than with a traditional cut

roof. With liner trays or composite panels the metal panels are

generally cut square, leaving a large V gap at the apex. Often the ribs

and corrugations on one slope do not line up with the ribs and

corrugations on the adjacent roof slope. If counter battens are used on

the liner trays they can be extended to the apex and mitred to the

counter batten on the adjacent roof slope, provided the ribs line up,

otherwise a ridge board will need to be installed. Alternatively with no

counter battens an inverted V-shaped metal trim has to be installed to

create an apex onto which the top tile or slate battens can be screwed

to get them as close to the apex as possible. The variations in roof

structure can make a big difference to the choice of roof space

ventilation and end ridge fixing method.

Ridge fixings

For fixing end ridge tiles, where the wind uplift is

high, and with dry fixed ridge systems, it is essential to have a semi

structural ridge timber/batten at the apex of the roof to provide a

suitable ground for the ridge tile screw fixings to fix into. Where the

roof structure is a traditional cut timber roof, provided the ridge

board is wide enough and the screw fixings are long enough, it is

possible to fix directly into the ridge beard. However, it is often

better to locate a timber tile batten above the ridge board and secure

it to the ridge board or rafters with straps to provide a wider timber

to fix into and allow a shorter screw to be used. With trussed rafters

there is no ridge board, so a suitably sized ridge batten needs to be

strapped down to each rafter. Due to the mitre joint at the apex of a

trussed rafter roof it is not sensible to fix the ridge batten directly

into the apex of a rafter unit with nails or screws. With liner-trays

and composite panels with a metal V trim at the apex, screwing the

timber ridge batten into the trim may be a problem, unless it is

installed from the underside before the V trim is installed. For more

information on end ridge fixings see Tiling Tips 12.

Mortar bedding

The ridge tiles are installed after the underlay, tile

battens, ridge batten and tiles/slates. If a dry fix system is being

used then the installation instructions should be followed. For

mortar-bedded ridges the first problem to overcome is access.

The generally accepted method is to sit on the ridge line

with one leg/knee on each roof slope with your back to the direction of

travel, which should be into the prevailing wind, or standing on a roof

ladder hooked over the ridge. You will need the ridge tiles, a bucket of

mortar, the end ridge fixings and the tools to do the job. First you

should wet out the underside of the ridge tiles and the top surface of

the tiles/slates, followed by lining out a row of ridge tiles in their

final position and marking with the tip of a trowel the edge line on

both sides, and the location of each cross bed joint.

The mortar should be a 1:3 cement sand mortar mix with

sufficient water to allow the mortar to stand up at least 75mm without

slumping. If the tiles are all to be mechanically fixed the sand can be

soft sand as used by brick layers in brick mortar. But if the ridge

tiles are not mechanically fixed the sand should be a 50/50 mix of soft

sand and screeding sand (sharp sand) to produce a mortar mix that is

similar to the mix that is used to make concrete roof tiles. The

addition of pigment should be done before or when the water is added to

the mix to ensure it is thoroughly mixed. |

|

The use of additives should be avoided or

used sparingly to achieve the best adhesion with the ridge and roof

tiles/slates.

A continuous line of mortar should be placed adjacent

to the edge lines marked on the surface of the tile. The width of the

bed should be approx 50mm, and the height will depend upon the shape of

the ridge tile, the roof tiles, and the pitch of the roof. When

the ridge tile is positioned on the mortar and levelled into the mortar,

the surface contact on the underside of the ridge should be at least

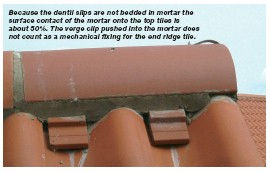

50mm.Where the depth of a tile corrugation is greater than 25mm, dentil

slips should be used to thin out the thickness of the fresh mortar.

Dentil slips should always have a bed of mortar under them to ensure

there is adhesion between the dentil slip and the top surface of the top

tile, also to even out the thickness of the mortar above and below the

dentil slip. The cross bed joints should be a minimum of 100mm wide and

set on a piece of tile or slate that bridges the top tiles/slates to

prevent the mortar coming into contact with either the ridge batten or

falling onto the underlay. If the height of the cross bed mortar is

greater than 25mm, pieces of tile should be used to thin out the fresh

mortar to bring it up to a suitable height.

When the ridge tile is laid into the fresh mortar it

should have a 50mm bed along each edge and side. It is not acceptable to

place mortar under the cross bed joint after the ridge has been laid as

a full 50mm of surface contact is not possible to achieve. Once three or

four ridge tiles have been laid it is best to level up the ridge tiles

and tap them down to achieve compaction between the ridge tiles and the

mortar without causing the mortar to slump away from the underside of

the ridge tile. If you do not tap the ridge tiles down there will be no

compaction of the mortar with the underside of the ridge, and the mortar

bond will not be complete. Any excess mortar should be trowelled off and

reused further along the ridge line. This process should continue to the

end of the ridge line, with the minimum disturbance to the top course of

tiles/slates. In hot weather if the mortar is drying too quickly,

sacking or wet carpet should be used to keep the chemical reaction of

the cement going to achieve the best possible mortar bond. Before the

mortar has gone off, the surface of the mortar should be trowelled up to

a smooth finish without disturbing the tiles or the ridges. Any excess

mortar should be removed with care to prevent smearing of the tile/slate

surface.

If the weather changes and rain threatens to wash the

surface of the mortar away, again sacking or old carpet should be used

to prevent cement washing down the surface of the roof. If cement

staining does occur, brick cleaner should be used to wash off the cement

marks after the rain has stopped. Once the mortar bedding has gone off

it is possible to install the screw fixings into the ridge batten/board

to the end and any other ridge tiles, ensuring that the screws are not

over-tightened.

Tips

- Install any ridge battens before

installing the top tile/slate battens.

- Remember to place mortar into the

pan of the tile before dentil slips are installed.

- After the ridge tiles have been

levelled, and the mortar trowelled up, do not let the mortar dry out

too quickly or disturb it by walking on the top tiles.

Ridge construction part 3 will deal with

accessories and fittings. |

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|