|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

All roof tilers know how to install ridge

tiles using mortar bedding, and because the technique has been passed on

from one generation to the next few can tell you why they do it that

way.

But when it comes to other forms of ridge tile fixing,

the recommendations are often not followed. If we look at the what, the

where, and the how, it is possible to understand why mortar bedding is

so popular and why it works.

Definitions

We need too start with some obvious statements that will help us

define what a ridge is. A ridge is the horizontal junction between two

roof slopes (duo ridge), or a roof slope and a vertical wall below a

roof slope, (mono ridge). If the roof junction is inclined, then it is

not a ridge, it is a hip or valley. A ridge (along with a top edge

abutment) should be the highest point of any roof slope, making it more

exposed than most other parts of a roof. A ridge is also one of the last

parts of the roof to be completed, making access to it often difficult.

Sizes and pitches

A ridge is normally formed of ridge tiles that are curved or angled,

and bridges the gap between the two roof slopes. To maintain a

weather-tight joint the ridge tiles should lap the head of roof tiles,

or slates, on each roof slope by a minimum of 75mm. To do this the width

of a ridge tile needs to be in excess of 150mm.

As it is almost impossible to mitre cut the head of the

top course of tiles to fit under a 150mm wide ridge tile, and because

the gap between the top course of tiles will vary with rafter pitch and

height of tile corrugation, ridge tiles are made to widths between 215mm

and 340mm, depending upon shape, material and manufacturer. In most

instances concrete and clay ridge tiles are available in two lengths –

450mm and 300mm – while continental clay tile manufacturers have lengths

from 330mm to 500mm, and fibre cement tiles are available up to 900mm

long.

Generally, the rafter pitch on each side of the ridge

of most buildings is the same. In reality they can vary from vertical to

12.5° on either side. With half-round, and some designs of angled ridge

tiles, it is possible to accommodate a wide range of rafter pitches from

12.5° to 45°.

If the roof slopes on both sides are steeper than 45°,

most halfround ridge tiles will not be wide enough. With angled ridges,

the angle should match as close as possible the true pitch of the tiles

on each roof slope. In most instances the length of each wing remains

the same, only the angle between them changes. Angles from 75° to 135°,

in 10° and 15° degree increments, are usually available.

To determine the angle of ridge needed, the following

procedure should be followed. Add together the rafter pitch of each roof

slope and take the result away from 180° (the sum of the angles of a

triangle). The result will give you the angle of the roof structure at

the apex. Add to this the angle difference between the roof tile and the

rafter pitch for each roof-slope (about 10° for plain tiles, 5° for

interlocking tiles, and 3.5° for slates). The resulting figure will be

the true dihedral angle between the top surfaces of the roof tiles or

slates at the ridge. Choose the nearest size ridge angle that is smaller

than your calculated dihedral angle (for 97° choose a 90 degree angle

ridge). If you choose a larger angle the outer edges will not touch the

tile surface and will give a thicker mortar bed appearance, while with a

smaller angle the outer edges will make contact with the tiles and hide

the majority of the mortar bedding.

Shapes

While half-round ridge tiles are the most popular shape, especially

for plain tiles and profiled interlocking tiles, angled ridge tiles are

popular with flat interlocking tiles and slates. ‘Hogs Back’ is a cross

between angled and half round – they were popular with clay plain tiles

but less popular now. Universal angle ridge tiles are a concrete angled

ridge tile with a short vertical up-stand along the edge to allow it to

be used with a variety of rafter pitches, as the name suggests. |

|

On the continent clay ridge tiles are

generally half-round or angled but with a flat top or a central rib,

often a reflection of the roof tile profile.

Capped angle and capped halfround ridge tiles are

another alternative. The cap is a raised section at one end that laps

onto the end of the next ridge tile, to protect the butt joint. These

should be jointed with mortar unless used with a dry-fix ridge system.

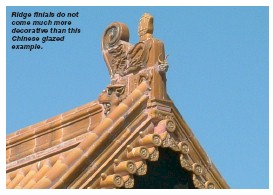

Half-round and angled ridge tiles are also available in

ornamental patterns, with rolls and crests along the apex, or finials at

one end. These are normally made of clay but can be found in a limited

range in concrete. Some ornamental ridge tiles are made in one piece,

while others are made in two or more pieces. Similarly, most decorative

finials are made in one piece, while others are bolted to a normal ridge

tile or block end.

Mono ridge tiles are generally available for both half-round

and angled ridge situation. The vertical leg of the mono ridge should be

long enough to cover the ends of the construction and provide a suitable

screw fixing onto a timber barge board or similar structure on the

vertical face.

Ridge accessories and fittings

There is also a range of fittings available for the ridge. Block

ends are vertical caps to the end ridge tiles that close off the ridge

to prevent birds entering the ridge. These are usually used with dry

ridge and dry verge systems. The block ends can be separate plastic

units or a complete end ridge tile unit. Dentil slips are narrow widths

of plain tile, or similar material, that are used to thin out mortar

bedding where profiled tiles have a deep corrugation. Thirdly, terminals

for gas flues and ventilators for mechanical extracts or soil pipes are

available for most ridge shapes. These terminals are ridge tiles with a

rectangular duct passing up through the centre section. The terminal

grill assembly is generally plastic for a ventilator and clay or

concrete for a gas flue as it needs to be non-combustible.

To achieve a continuous ridgelevel roof-space

ventilation system there are dry ventilated ridge systems that have

grills along the leading edge of the ridge tiles, and ridge-to-ridge

seals with mechanical fixings between the ridge tiles, that eliminate

the need to mortar-bed the ridge tiles. For very exposed locations, and

where there is a lot of roof structure movement, dry-fix ridge systems

are also available with no ventilation. Some are similar to the dry vent

systems, and some are very different relying on a waterproof membrane

under the ridge tiles to protect the roof structure below.

Lightening conductors are often installed along the

ridge line, either under the ridge tiles with externally exposed strike

plates, or along the side of the ridge on slate straps. Whichever system

is used it should be integrated into the ridge during construction, as

the location of the straps, plates and tape must not interfere, or

weaken, the ridge installation.

Tips

- Try to select all ridge components

from the roof tile manufacturer to ensure compatibility.

- Check that the ridge tile and

components are all suitable for the rafter pitches on each roof

slope.

- Set the top tiles/slates as close to

the apex of the roof as possible to achieve at least 75mm of lap

between the ridge tiles and the top tiles/slates.

Ridge construction part 2 will deal with

the installation of the ridge components. |

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|