|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Nail-holes in roofing slates and tiles are

taken for granted. We expect them to be there, but their size, shape,

and location are critical to fit the slates and tiles correctly on a

roof. If they are not formed correctly they can become a big problem.

Why have nail-holes?

There are interlocking tiles that do not have nail-holes in them.

Provided there is a means of locating and fixing the tiles against wind

uplift, they are not always needed. Often they are provided if they are

needed. With interlocking tiles at 45° and above, it is essential that

every tile is fully nailed to prevent the tiles sliding off the battens.

This means that if the tile has two nail-holes, then two nails must be

used to fix it.

At below 45°, if the wind uplift forces are greater

than the deadweight resistance, and below the combined resistance of the

dead weight and the nail pull-out resistance, then nailing tiles is

appropriate. If the tiles in the main body of the roof do not require

nailing, the perimeter tiles must be nailed to comply with BS5534, the

code of practice for slating and tiling. There may also be instances in

very exposed locations where tiles will need to be nailed and clipped.

Slates do not have nibs to locate them on a batten, so every slate must

be nailed, or they could be hooked.

Location

The position of the nail-hole is critical. With interlocking tiles the

nailhole is generally located in the headlap area and should coincide

with the centreline of the tile batten. If the nail-hole is outside the

middle third of the batten, there is a high risk of splitting the

batten. If the nail-hole is too close to the top edge of the tile, the

ability of the nail to stop the tail of the tile lifting in the wind is

reduced; the further the nailhole is down the tile the better. If the

nail-hole is too far from the top of the tile the greater the risk of

water seeping up the face of the tile by capillarity. When water reaches

the nail-hole, it will drain down it, especially on shallow rafter

pitches. This is often why at shallow rafter pitches the head-lap is

increased, or tiles with no nail-holes are used. The distance in from

the edge of the tile is not always critical, but is best kept away from

the trough of a corrugated tile or the side lap of the tiles above,

especially if there is a recessed interlock.

Sometimes this is unavoidable as with a single pantile,

where often the nail-hole position will restrict the minimum pitch

parameter. Some tiles will have the nail-hole located in the nib where

the nail is driven into the narrow edge of the batten. This location

protects the nail-hole from water seeping in but has a very low wind

uplift resistance and the nail can often split the thin section of the

batten. Nibs are also vulnerable to being broken in transit rendering

the nail fixing ineffective.

With slates, being double lap, their location is

dictated by the recommended batten gauge for a given size, exposure, and

rafter pitch. The nail-hole location, about half-way down the slate

length, makes the ability of the nail to resist wind uplift forces that

much better than if located close to the head. However, being close to

the centre makes it vulnerable to water seeping sideways from the side

lap of the slates above. To compensate for this the nail-holes need to

be as far away from the side lap as possible, but not too close to the

outer edge as the nail-hole will be weak. With some materials you can

get as close as 20mm from the edge, while with others it can be as high

as 40mm.

The distance the nail-hole is up, and in, from

the edges of the slate above will determine its pitch performance. This

is why shorter wider slates perform better than longer narrower slates

at low pitches. With salvaged slates it is common practice to punch new

nail-holes in the slate either closer to the centre of the slates,

and/or above the original damaged nail-hole.

This practice can present problems – unless the rafter

pitch is very steep water may reach a nail-hole and leak in. Also

additional nailholes will further weaken the slate at the point of

maximum stress in the slate, causing the slate to fail between the

nail-holes. |

|

Size

The size of the nail-hole should be just a little bit larger than the

diameter of the nail that is being used to fix the tile or slate. With

concrete, slate and resin slate materials, the nail-hole punch has to be

tapered to allow the punch to return without damaging or tearing the

sides of the hole that it has just formed, so the hole will be slack

under the nail head, but tight where it penetrates the batten. The

nail-hole should never be smaller than the nail diameter, to prevent the

correct fixing nail being used. Forcing a nail into a smaller nail-hole

could damage the nail or the tile.

The underside of the nail-head should always make

contact with the surface of the tile to ensure there is the minimum of

tile lift before the nail starts to do its work of resisting the wind

uplift forces. The bigger the gap between the underside of the nail-head

and the tile, the greater the risk of tiles rattling in the wind. Some

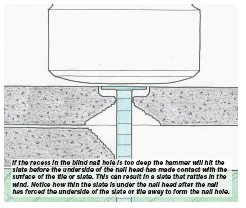

tiles have a small recess around the nail-hole to accommodate the

thickness of the nail head. This design feature can prevent the

underside of the nail head from making contact with the surface of the

tile, especially if the nail head is very thin or the recess is too

deep. It also results in the tiler’s hammer coming directly into contact

with the slate. The practice of leaving the tile nail clear of the

surface of the tile is very common as over-driving the nail can result

in the tile breaking. Skill and care can be used to ensure the underside

of the nail head is as close as possible to the surface of the tile. For

every 1mm the nail head is above the tile, there is 1mm less penetration

of the nail into the batten, and, therefore, less grip on the nail.

With slates the nail-holes are often pre-punched

for a given gauge/head-lap. Provided they are done correctly with a

correctly adjusted sharp punch the spall around the hole on the upper

surface of the slate will allow the nail head to sit flush or slightly

above the top surface of the slate. With a blunt punch the spall will be

larger and will affect the depth of the recess and the remaining

thickness of the slate around the nail-hole. With some man-made double

lap slates, recessed blind nail-holes are provided to allow the slater

to punch through with the fixing nail. As with interlocking tiles, the

depth of the recess is critical to stop the slates rattling. Sometimes

the thickness of the blind nail-hole is more than half the thickness of

the slate, resulting in a large section of spall on the underside of the

slate, weakening the slate around the nail-hole position.

Tiles or slates with missing or poorly formed nail-holes should be

rejected before or during construction as defective. It may be that the

nail-hole defect can be corrected. But often it can not be and renders

the tile or slate as unusable.

Tips

- Using a correctly adjusted nail-hole

punch for slates will produce a clean nail-hole without weakening the

slate.

- Drive the nail-head down to almost

touch the surface of the slate or tile to give the best wind uplift

performance of the nail.

- It is cheaper to install extra nail

fixings during construction than to replace one broken or slipped tile

or slate after the scaffolding has been dismantled.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|