|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

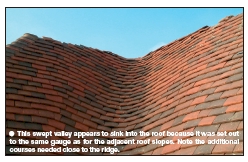

There is a notion that pitched roofs look

more romantic if the plain tiles sweep gently from one roof slope to

another, without the interruption of a sharp corner or a break in the

construction, just like a thatched roof.

Swept valleys are fairly rare, require a lot of tile cutting,

and can be costly to construct. Therefore, understanding their

advantages and disadvantages before specifying or constructing a roof

incorporating a swept valley is essential.

Swept valley

A swept valley is a valley formed of tapered tiles nailed to a

support board that bridges the junction of two roof slopes at an

inclined valley. Each horizontal tile course is maintained and no

special valley tiles are needed. The design of a swept valley is

traditional with stone slates, and to some extent natural slates.

Forming a swept valley with plain tiles is almost impossible to achieve

and comply with British Standards 8000 Part 6 and 5534.

For a swept valley to work the rafter pitches on both sides

of the valley must be the same (ideally steeper than 40°). It also works

best if there are two swept valleys that meet at a ridge that is part

way up a main roof slope, such as a dormer. In this situation the curve

is run up and lost into the roof slope above. The actual junction is

covered by the ridge tiles that are turned up the roof and also lost

into the roof slope. If the valley is not part of a matched pair, the

valley will meet a square ridge junction. This will leave a curved

exposed section that will need a large curved lead saddle to cover up

the difference between the two.

Support boards

Three boards need to be installed to ensure that the tiles form a

curve around the valley. The underlay should be installed in the normal

manner with a 225mm wide timber (not ply) board laid straight down the

centre of the valley. Preferably this will be the same thickness as the

tile battens, and nailed into each rafter. The width of the board can

vary slightly depending upon the rafter pitch. The other two boards

should be feather edge boards at least 100mm wide (fence pales) fixed

down the sides of the centre board with the thinnest edge facing the

centre line. These should be positioned to halve the angle between the

rafters and the first support board, and should be nailed to the support

board.

With the adjacent roof slopes, the support boards should form

five surfaces onto which the tiles can be nailed. The tile battens on

each roof slope should be cut against the thick edge of the feather edge

boards to finish flush with the top surface and to align horizontally

with the battens on the adjacent roof slope. None of the battens are cut

around the curve.

Eaves & guage

As the swept valley forms a curve (most eaves fascia boards or open

rafters meet at a sharp right angle at the bottom of the valley) the

under eaves course of tiles needs to be set to meet at a mitre parallel

with the fascia board. The first full course of tiles should be set in

the curve as for the rest of the valley. However, some people like to

keep this course parallel with the fascia, mitre it with a soaker, and

form the curve of the valley on the second full course of tiles. Either

is acceptable.

The distance up the centre line of a valley will be longer

than the distance up the rafter for the same vertical rise. To achieve

the same number of tile courses around the curve of the valley, the

gauge of the tiles on the centre line of the valley will be greater than

for the tiles on the adjacent roof slope. |

|

This means that either the whole roof must

be set out at the minimum gauge of 88mm, such that the tiles on the

centre-line of the valley do not exceed 100mm gauge, or if the roof is

set out at 100mm gauge, the tiles on the centre line of the valley will

have a gauge of more than 100mm. The closer to vertical the rafter pitch

is, the smaller the difference in gauge. The difference in gauge will

depend upon the rafter pitch. Unless the rafter pitch is steeper than

59° it will be impossible to keep within the 88mm-100mm gauge parameters

and the maximum and minimum head-lap requirements of BS5534, without

resorting to other means.

One means of overcoming the problem is to lay sheet lead

soakers, or other similar material, between each tile course around the

valley. The gauge increasing is not a problem with stone or natural

slates as longer slates can be used up the valley to maintain the

required headlap for the true pitch.

Side lap

As the tiles progress around the valley on each course from

one roof slope to the other, the tiles must be cut to a taper to fit.

Tapering the tiles makes the tiles at the leading edge narrower and the

perp joints should be maintained on the curve and lost in the adjacent

roof slope. Each tile joint on the curve should fall in the centre of

the tile below to give the maximum side lap with the joint on the course

below. This is best achieved by setting out the valley from the centre

line and working out onto each adjacent roof slope. BS5534 requires a

minimum side lap of 55mm.

As the tiles are cut to a taper and work progresses up the

roof, the side lap will increase to the point where a tile is not wide

enough and a tile-and-a half is needed. When it is possible, two tiles

should be cut to finish on the tile-and-a-half. The resulting cuts will

mean that many of the side laps will be less than 55mm. Laying courses

of sheet lead soakers or similar material between each course of tiles

around the valley will protect the lack of adequate side lap. This is

not a problem with slates as wider slates can be used around the valley.

As there are no battens around the curve of the valley, the

tile nibs need to be removed were they in contact with the support

boards. Each tile that has been cut to a taper needs to be nailed twice

to the support board. If the nail hole has been cut off, it should be

re-drilled as two nail fixings are essential. One central nail fixing

would coincide with the joint of the tiles above and be prone to

leaking.

Tips

- Swept valleys may look good if done

correctly but will not comply with British Standards, unless large

soakers between each course of tiles are used.

- The fixing of the support boards and

the maintaining of the horizontal line around the curve is critical.

- Down the centre line of the valley the

gauge of the tiles will be in excess of the tiles on the main roof

slope. Never maintain the same gauge around the valley as this will

generate additional tile courses and look strange.

- Unless the side lap exceeds 55mm, a

large soaker between each tile course will be needed.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|