|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Like it or not there are occasions when the best solution to

venting a soil pipe, bathroom or kitchen is to duct it out through the

roof.

To achieve this, ventilation tile or slate

provides the neatest and simplest interface with the roof covering to

ensure the roof remains watertight. But what about the fixings?

History

When vents first needed to pass through a pitched roof, a pipe was

extended well above the roof and bedded in mortar as it passed through

the tiles or slates.

It was soon found that this was not a long-term

solution, so a lead collar, called a lead slate, was installed around

the pipe and integrated into the surrounding roof tiles. This

arrangement worked well, especially before the installation of roof

underlay. With no underlay, soil pipes needed to terminate approximately

900mm above the roof to prevent smells drifting back into the building

through the tiles.

With the introduction of underlay it was

possible to vent soil pipes closer to the roof covering, allowing more

discreet terminals to be installed.

Eyebrow

The first types of vent tiles were called

eyebrow vents. They were mostly made of clay or concrete in the shape of

an eyebrow. Being made of clay or concrete they were as heavy, or

heavier, than the tiles that surrounded them. Therefore they were less

affected by wind uplift than the adjacent tiles, and provided they were

nailed or clipped in the same way as the adjacent tiles they were

adequately fixed.

Mushroom

The next generation of vents were the mushroom vents. These were the

first of the plastic units that could be installed in a standard roof

tile or slate, or as part of an all plastic unit.

Many were lightweight - made of vacuum-formed

pvc sheet material. The all-plastic vents, being lighter than the

surrounding tiles or slates, needed more fixings than the surrounding

tiles. Some interlocking vent tiles had tabs that rotated under the

right hand interlock to locate it firmly to the adjacent tile, which

helped to hold them in place, but the majority did not have any form of

additional 'holding down' device.

In-line

The most recent generation of vent tiles are the in-line vents, where

the surface of the tile or slate is a grill, with baffles to prevent

wind-driven rain from entering the pipe located within the depth of the

tile and the batten cavity.

Like the mushroom vents these are very light and need

to be nail and clip-fixed more securely than the adjacent concrete and

clay tiles.

Slate

The majority of the slate vents are manufactured in plastic to lap into

the slate array with the minimum number of slates above and below the

slates needing to be cut. Being laid in among other slates helps to hold

the slate vent down.

But where the main body of the slate vent is

exposed, the wind suction force can lift the vent, as the plastic is not

as rigid as a natural slate, and therefore needs an additional fixing

such as a tail rivet.

|

|

Wind suction

Wind suction forces on roofs are resisted in three ways. Firstly by the

dead weight of the tile or slate, secondly by the nail and clip fixings,

and thirdly by the gaps in the vent (through which air can be sucked).

With plastic vent tiles and slates the dead

weight is low, placing more load on the nail and clip fixings. This is

slightly offset by air being sucked up through the vent tile grill,

especially with the in-line variety.

It is rare to lose a vent tile as many are

joined to a vent pipe or duct by a flexible pipe, but this should not be

relied upon as the main fixing.Fixings

In most instances all-plastic vent tiles and slates will need a higher

level of fixing than the surrounding tiles and slates. Therefore, it

would be wise to always nail and clip interlocking vent tiles, fully

nail plain tile vents, and nail and tail rivet all plastic slate vents,

regardless of the tile or slate fixing specification for the roof.

Integrity

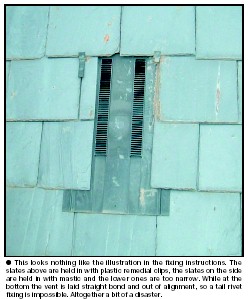

The majority of vent tiles are often installed not by the slater or

tiler, but by the plumber or ventilation engineer, after the roof has

been finished.

This often results in: the vent tile, and the

surrounding tiles and slates, not being reinstated correctly; no

underlay seal to prevent water on the underlay draining into the roof;

tiles and slates kicking up; and generally leaving a weakness in the

roof covering.

Provided the appropriate vent tile or slate is

used, there should be no reason for a vent to compromise the integrity

and security of the roof.

It is worth noting that slate, clay and

concrete roof tiles and slates will always last longer than a plastic

vent tile or slate, and will therefore need replacing during the life

span of the roof.

Tips

- Use the right vent tile or slate

appropriate for the tiles or slates being used on the roof

- Choose a plastic vent tile with an

integral interlock device on the right hand interlock, for

interlocking tiles, where possible

- Always follow the fixing instructions

supplied by the manufacturer

- Hold down the leading edge of a

plastic slate vent with a copper disc rivet

- Plan to install all vent tiles when

the tiles and slates are laid, not after the roof is finished

|

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|