|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Side abutments, where the left or right-hand edge of a roof meets a

vertical wall, look very similar to a verge, and in many ways they are.

But, for a watertight junction, the construction is very different.

If the side abutment is not at right angles to

the line of the battens then water running down the roof could either

run into, or away from, the side abutment; these are called raking

abutments and are outside of the scope of this article. Provided that

the side abutment is at right angles to the line of the battens then the

following comments will apply.Battens

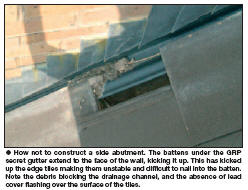

In many instances the tile battens at a side abutment will finish

hard against the abutment wall. This is acceptable with profiled

interlocking tiles where a full cover flashing is used correctly, or

with proprietary abutment flashing units. But for all other situations a

secret gutter and cover flashing is the recognised best practice

solution. This will require each batten to finish 38 to 50mm away from

the abutment to allow the drainage channel in the lead or GRP secret

gutter, to be formed in the depth of the batten, against the abutment

wall. Provided the last rafter is located 50mm away from the abutment

wall, fixing the end of the batten will be easy, but if the rafter is

hard against the abutment wall an additional 50 by 50mm batten will need

to be fixed to the side of the last rafter to support the end of the

batten that stops 50mm short of the wall. With a lead secret gutter and

cover flashing detail the lead drainage channel will not support its own

weight and will need to be supported with a 50 by 50mm batten fixed down

between the wall and the last rafter and screwed into position.

Eaves

At the bottom of an abutment where a secret gutter is installed

there must be a clear path for any water in the secret gutter to drain

out into an eaves gutter. This can be achieved by finishing the underlay

support board and over fascia ventilation grill short of the abutment,

or to cut a notch in the fascia board, to allow the secret gutter

channel to run through and finish into the guttering. However there is a

potential clash with the underlay that will be installed below the GRP

secret gutter and have to rise up onto the top of the underlay support

tray. There is not an issue with a lead secret gutter as bitumen

underlay should not be laid under a lead flashing or gutter in the first

place. An alternative solution is to reduce the pitch of the secret

gutter channel approaching the eaves and install a lead fantail to allow

the water to flow over the fascia board into the gutter. Where the

bottom of a side abutment meets lower tiling a lead fantail is essential

to bring any water out onto the head of the lower tile.

Bond

When setting out the tiles the bond pattern of the tiles is an important

consideration. The tiles are likely to be either straight bond or half

bond (broken bond), but occasionally with a mock bond appearance the

true bond is achieved using a quarter or three quarter tile. Depending

upon which bond you have will depend on the module that you have to use

to finish at a side abutment with the minimum number of uncut tiles. The

traditional method of finishing on a whole tile is to shunt the tiles in

or out along the row. There are always occasions when it is impossible

to finish on a whole tile and therefore tiles will need to be cut to

fit. With any piece of tile that is smaller than half the width of the

original tile there is a risk that fixing the small section of tile will

be difficult, especially if a secret gutter is being used.

Fixings

A continuous lead cover flashing is in effect a continuous clip that

helps to hold down the edge row of tiles, therefore if the fixing

specification requires the edge tiles to be clipped, the lead will

suffice on a left hand abutment.

|

|

|

Where all perimeter tiles are required to be mechanically fixed using

nails there may be a problem achieving the nail fixing for a flat cut, or

half tile, as the nib is often cut off to prevent it clashing with the

secret gutter and the nail hole coincides with the secret gutter material,

or misses the end of the batten. In these

instances it is better to finish the side abutment 20 to 40mm away from

the side abutment and extend the lead cover flashing over the top

surface of the tile to achieve the required minimum side lap cover. The

side lap dimension is not measured from the face of the wall but from

the edge of the tiles.

Flashings

With interlocking tiles, soakers must never be used. Therefore a lead

cover flashing will be required. With flat interlocking tiles the

minimum side lap distance should be 150mm. However with profiled

interlocking tiles side lap cover is not so easy to determine. Many

profiled interlocking tiles have a trough that is flush with the side

interlock, such that unless the flashing goes over a full roll water

creeping in between the flashing and the tiles will run onto the trough

of the tile and could run off the edge. The recommendation of the Lead

Sheet Association is that the flashing covers a full roll. Depending

upon the location of the roll at the side abutment will determine the

actual side lap cover distance.

Tiles like a single pantile can present a

problem as the bulk of the profile is a trough and the nail hole is

situated at the bottom of the trough. Therefore to cover a complete roll

requires one and a half tile width to be covered with flashing or the

edge tile to finish as a cut half tile, making it impossible to nail fix

into position. Provided the rafter pitch is steep, finishing the

flashing in the trough of the first tile appears to be adequate but will

only have a cover of 110mm rather than the minimum 150mm. However at

rafter pitches close to the minimum pitch for the tiles water leakage

problems will occur. As a rule of thumb rafter pitches less than 45¡ã

should have the wider flashing, but there is no definitive ruling or

test data for this.

Soffit

At the head of a side abutment there is often a diminishing space

where the side abutment meets a soffit. This space is often left

unfinished and can allow birds to enter the roof and nest. Where the

roof and the soffit meet it is impossible to nail the top tile and

almost impossible to install a flashing. In these instances it is better

to install a vertical board on a timber framing between the soffit and

the tiling, to allow the top tile to be installed correctly and a lead

flashing to dress down over the head of the top course of tiles. While

this may form an additional section of side abutment between the soffit

and the base of a valley, it is better than leaving it open for birds

nest in the roof.

Tips

- Where possible the tiles should be set

out to finish at an abutment with a whole tile.

- Soakers should never be used at a side

abutment with interlocking tiles.

- The end tiles at a side abutment

should be set so that they do not kick up and the nail fixings do

not puncture the secret gutter.

- The construction of the top and bottom

of a side abutment are as important as the middle.

|

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|