|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

In the pitched roofing industry we all know that British Standard 5250,

the Code of Practice for the Control of Condensation in Buildings, and

the Building Regulations Approved Document F2, have for many years

recommended that the way to control the build up of condensation in

roofs is through the use of ventilation. While systems that avoid the

use of ventilation have been marketed by some companies, ventilation is

still the most popular system for complying with Building Regulation F2.How it works

The basic requirements for ventilating a traditional cold loft space

are that air should enter the loft at the lowest point on one side of

the roof and exit on the opposite side of the roof. Water vapour rises

up through quilt or fibrous insulation, and meets the air in the loft,

where some of the moisture is absorbed - the quantity depends on the air

temperature.

Warm air can absorb more water vapour than cold

air. If the air layer directly above the insulation is constantly

changing it stands a good chance of absorbing most or all of the water

vapour and take it outside. The warmer the air in the rooms below the

insulation the higher the amount of moisture that can be absorbed. The

cooler the loft the less moisture that can be held before condensation

forms. Consequently if air leakage into the loft is full of moisture

then the risk of condensation forming in the loft increases. This can be

reduced if a vapour check layer is introduced below the insulation such

as foil backed plasterboard, or a layer of polythene, along with sealed

holes and openings.

Over time it is almost impossible to keep out

all water vapour from the loft. The most vulnerable period for

condensation forming in a cold loft is immediately after occupation of a

new building when the plaster walls and ceilings are drying out. Excess

water vapour finds its way into the cold loft. During cold weather the

risk of condensation forming is greater.

Extreme conditions

Air flow through the loft can discourage condensation.

Most days we have a slight breeze causing a

small positive wind pressure on one side of a roof and a small negative

pressure on the opposite side. This pressure difference can drive a flow

of air through the loft provided there are suitable air gaps on each

side of the roof linked to the loft space. But if there is no wind, then

there will be no positive or negative pressure to drive the air through

the loft.

Therefore, air that leaks through the

insulation will be warmer than the air in the loft and will try and rise

to the top of the roof. It will become trapped under the ridge and start

to cool, where it will form condensation on cold surfaces. If there was

a vent at the ridge, the air would be carried outside and cease to be a

problem.

Air should never be allowed to enter at a

ridge, only leave. It is for this reason that most roof tile

manufacturers will recommend eaves to ridge ventilation as it will cope

with both the wind and no wind situations. (Eaves to eaves ventilation

is designed to work with a slight breeze.)

There are occasions when all buildings will

experience hurricane force winds. Wind pressure will be such that the

air will pass through the loft very quickly and over-ventilate the loft.

The faster the air passes over the quilt, or fibre insulation, the less

efficient the insulation is.

Quilt insulation works by trapping air between the fibres, which forms

the insulating layer. If the air passing over the quilt can wash through

the fibres then a percentage of the air in the insulation will be washed

out and not be as efficient. It is possible to encapsulate the

insulation or cover it with a layer of material such a vapour permeable

underlay (VPU) which keeps the air in the insulation and separates it

from the colder ventilation air. Alternatively if a building is in a

very windy location it may be more appropriate to reduce the cross

sectional area of the ventilation grills to reduce the airflow through

the loft.

|

|

Recommendations

The size of the grills through which air enters and leaves a roof is

prescribed as a continuous 10mm gap at eaves or low level, with a

continuous 5mm gap at ridge or high level.

These figures are a compromise. On calm days

they are too small, on very windy days they are too large. Temperature

and moisture levels constantly change, making a precise level of

ventilation almost impossible to achieve. Although over time more water

vapour should leave the loft than enters it from below.

There is an argument that states that if you do

not have any underlay, or boarding under the tiles, and there has been

no history of condensation problems, there is no need to introduce

ventilation. The present roof ventilation requirements relate to roofs

covered with BS 747 type 1F or 5U bitumen underlay. Therefore, if a VPU

is used the amount of ventilation should be less than for a bitumen

underlay and more than for no underlay. There is no test data to

determine the correct level of ventilation. Therefore, the levels of low

and high level ventilation should remain unchanged for VPUs.

Things to avoid

There are some practices that should be avoided:

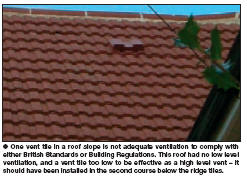

- Having ventilation tiles halfway up

the roof slope. This practice can allow condensation to form below

the level of the vents and in calm conditions still traps air up

close to the ridge

- Having a few very large vent tiles or

grills rather than a continuous slot or grill. The larger the vent

or grill, the greater the distance between the vents or grills

resulting in a massive localised air flow close to the vent and

little or no air flow as you move away from the vents

- Placing large vents on one side of the

roof directly in line with vents on the opposite side. This can

create a wind tunnel across the roof between the large vents and no

air movement as little as 600mm away

- Installing more high level ventilation

than there is low level ventilation. It is important to ensure that

air enters at low level and exits at high level and not the other

way around. If there is more ventilation at high level, air will

enter the loft at high level and drag, or suck in fog, mist or rain

The worst combination is four large vent

tiles positioned at mid span on each face of a pyramid roof in an

exposed location.

Conclusion

- Always install low level roof space

ventilation into a pitched roof

- Always try and install a continuous

grill or strip ventilator rather than large individual grills or

vents, as they provide a more even flow of air through the

loft

- Where possible install high level

ventilation to reduce condensation in calm conditions

- In very exposed locations use a VPU

over the insulation to improve the quilt insulation's performance,

or reduce the ventilation area to prevent over-ventilation of the

loft.

|

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|