|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

With more and more buildings being

designed with rooms in the roof, the more we are seeing rigid insulation

being placed above the rafters, just below the battens. By placing

insulation boards above the rafters , to reduce the cold bridging effect

of the rafters, the greater the need for counter battens.

Whenever a rigid board, or sarking, is placed

between the rafters and the battens of a slated or tiled roof, it is

essential to lift the battens clear of the rigid board to allow any

water on the underlay to escape. Regardless of the type of underlay,

water in the form of condensation, melted snow or rain entering the roof

before the last ridge tile has been installed will try and run down the

underlay. Unless it can run under the battens it will dam up against the

first batten it meets and run sideways until it can find a way through

the underlay (usually down a batten nail hole). Provided the battens are

clear of the underlay by more than 6mm, water will take the easiest

route and drain off into the gutter at the eaves. To achieve a

consistent gap between the battens and the underlay, timber counter

battens should be fixed through the rigid board and into the rafter

below.

But that's not the only reason why counter

battens are needed. With rigid insulation boards it would be expensive,

especially with plain tiles, to fix each batten with helical nail

fixings, through the insulation into each rafter. It is much more

economical to use fewer helical fixings to secure the counter battens

through the insulation into the rafters below, and use cheaper nails to

fix the battens into the counter battens.

The thickness of the counter batten can vary

depending upon the rigid board material. All batten nails need to

penetrate a structural material by a minimum of 38mm. Where insulation

board is used that has no structural fixing quality, the counter batten

needs to be the full 38mm deep to provide the full nail penetration

depth. With rigid boards such as plywood and oriented strand board the

thickness of the board can be used as part of the nail penetration depth

provided the board is adequately secured to the rafters first. This can

either be achieved by using a nail long enough to pass through the

counter batten, rigid structural board and into the rafters by 38mm.

With this method the counter batten contributes to the batten nail

penetration depth. Alternatively the board is nailed directly to the

rafters before the battens are nailed through the counter batten into

the rigid board and rafter. With this arrangement the counter batten

only qualifies as a spacer and can not count as a part of the batten

nail penetration depth.

Weight of tiles on steep roof slopes with

counter batten used with insulation board, can cause the helical fixing

nails to bend, as the section of the nail passing through the insulation

is unsupported. In this situation the ends of each counter batten should

be fixed to horizontal restraining battens equal to the depth of the

insulation board. Provided each end of the counter batten is fixed in

this manner they will not rack and will allow the helical counter batten

fixing to transmit safely the tension and compression loads.

|

|

The fixing of

counter battens through any form of board is not easy. With the roof

boarded out it is difficult to see the rafter that you are fixing into. Accurate marking of the

boards as they are installed, or setting chalk lines from top to bottom,

is essential to maintain the line of each rafter. If the underlay is

laid before the counter battens the rafter lines need to be transferred

to the surface of the underlay. The thicker the insulation board and the

thicker the counter batten, the greater the risk that the helical nail

fixing will miss the centre line of the rafter below. A fixing that

misses the rafter or splits the edge fibres of the rafter will not be

transferring any load back into the roof structure.

At the apex of a ridge the counter battens

should finish with a vertical mitre cut. This ensures that the top

tiling/slating batten on each side will not finish on a joint and is as

far away from the end of the counter batten as possible.

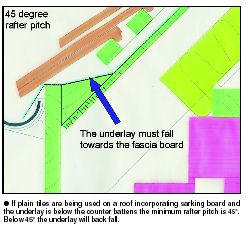

Provided underlay is installed over the counter

battens, the counter battens can be finished behind the fascia board.

But where the underlay is laid under the counter batten the bottom of

the counter batten should finish close to the bottom edge of the first

tile/slate batten to allow the underlay to pass out over the fascia

board without having to rise. A rise in the underlay at this point will

allow water on the underlay to be trapped and pond, where it could drain

through an end lap in the underlay.

Counter battens installed with rigid insulation

material should be a minimum of 38 by 38mm fixed through the insulation

into the structure below with helical fixings. The length of the fixings

should equal the thickness of the insulation plus 80mm and the ends of

the counter batten should be fixed to a restraining batten.

Counter battens installed with rigid structural

boards do not need helical fixings and do not require a thick counter

batten. However the length of the counter batten fixing nail should be

equal to the thickness of the counter batten plus 40mm provided the

rigid structural board is adequately fixed to the rafters.

Where the counter batten is used as a spacer

the length of the batten nail should be equal to the thickness of the

slate/tile batten plus counter batten + 40mm. The wider the rafters, the

thinner the combined thickness of the insulation and counter batten the

better the chances of the helical fixing nail entering the middle third

of the rafter and achieving an adequate pull out resistance.

As with any system of components, the more

layers the more options are available and the more things that can go

wrong. |

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|