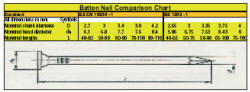

For years it has been taken for granted

that tile batten nails are 65mm long by 2.65, 3.0 or 3.35mm diameter

steel wire nails. But why?

Nail penetration

Since September 1997 it has been recommended that all battens used

for roof tiles and slates should be a minimum of 25mm thick to allow the

tile nail to get a full 25mm of grip. If we deduct the batten thickness

from the length of a 65mm long nail, the remaining 40mm of nail

penetrates into the rafter or counter batten. If batten thickness was

increased, nail penetration into the rafter would be reduced, so a

longer nail may be needed.

The figure of 40mm penetration for the batten

nail is very traditional, as in reality every roof will have a different

minimum nail penetration requirement. For instance, the nail penetration

for plain tile roofs could be less than for an interlocking tile roof.

It is better to have a nail that is longer than needed as there is a

risk that if the nail penetration is too short, serious roof damage may

occur during hurricane force winds.

Wind uplift load

Batten nails are one of the primary fixings for the transfer of wind

uplift loads on the roof into the roof structure. Wind suction acts on

the tiles, the tiles transfer some of the load via the nails or clips to

the battens, and the battens in turn transfer the load to the rafters

and so on down to the foundations. The size of the load that is

transferred from the batten to the rafter will depend upon four main

factors:

- Rafter centers. Roofs with rafters at

400mm centers have 30 percent more batten nail fixings than those

with rafters at 600mm centers.

- Batten gauge for the tiles. Plain

tiles with a batten gauge of 100mm will have 71 percent more batten

nail fixings than an interlocking tile with a gauge of 340mm.

- Dead load of the roof tile. Part of

the wind load on the exposed surface of the tile will be resisted by

the dead load of the tile. This will depend on the weight of the

tile, the distance to its centre of gravity and the rafter pitch of

the roof slope.

- Anticipated wind uplift load. This is

the predicted load that will act on the roof once in a 50 year

period, as defined by calculation in BS 5534, Code of practice

for slating and tiling: Design 1997.

Remember that battens take 100 percent of

the wind uplift load acting on the underlay when the underlay is

positioned directly under the batten.

By calculation, the design load on one

square metre of roof slope can be found. Having deducted the dead load

of the tiles the remaining load should be divided by the number of

batten nail fixings per square metre of roof, to define the withdrawal

load on each nail. |

Nail grip

The action of a wind uplift load is to pull the nail out of the

rafter. The amount of grip the nail has in the timber is critical and

determined by three main factors:

- Exposed surface of the nail. The more

exposed surface that comes into contact with the rafter timber, the

greater will be the grip. The exposed surface area is defined as the

circumference of the nail, times the nail penetration depth, less

the nail point. A nail with a larger diameter provides more grip

than one of a smaller diameter.

- Surface finish of the nail. Nails that

are smooth are easier to pull out than those with an improved

surface, such as ring shank grooves or a spiral square section.

- Timber grade being nailed into. Higher

density timber will grip the nail better than a lower density

timber.

BS 5268: Part 3: Structural use of

timber, can assist further with the resistance of different fixings to a

withdrawal load.

European standard

In January 2000, European standard BS EN 10230: Part 1: Steel

wire nails for general applications, became effective. Now all steel

batten nails should be supplied to the new standard. The 2.65mm diameter

increases to 2.7mm, and 3.35mm increases to 3.4mm. Whilst these figures

are not large, roofs constructed using batten nails to the old British

Standard 1202: Part 1: 1974 may be fit for purpose, but may not truly be

said to be constructed in accordance with current British and European

Standards, and this fact may invalidate a manufacturer's guarantee. The

specification for nails used with the new generation of nail guns fall

into the same category, especially with regard to diameter and head

design.

Galvanized nails

The new European Standard for steel nails states that the nail

diameter is measured before galvanizing. Logic says that for bending and

compressive strength the pre-galvanized dimension should be used. For

the withdrawal load on the nail, the post-galvanized dimension may be

used.

Batten nail calculations

Whilst there are so many variations to be considered, experience

tells us that for most homes in populated parts of the UK a 65mm long

batten nail is adequate. But as soon as the building rises above three

storeys, or the roofing material becomes lighter, and the exposure of

the building requires a higher level fixing specification, it is likely

that the size and type of batten nail will need to be calculated. Major

tile manufacturers will automatically calculate the tile batten nail

size at the same time as the tile fixing specification, others may not.

Advice

Seek the advice of the tile manufacturer early in the specification/

tendering process. Also check that the batten nails being used comply

with the new BS EN 10230 specification. |