| Bryn

Williams, quality manager at rainscreen cladding manufacturer Steni UK,

discusses the findings of an ecological comparison of facade renovation

systems. |

| Rainscreen

cladding systems are something of a modern-day wonder product given their

ability not only to transform the aesthetics of a building but also

appreciably upgrade its performance, specifically in the area of thermal

insulation. |

|

| Not only can such

systems breath new life into tired, badly-performing buildings such as

offices and residential tower blocks, they are also a highly effective

method of branding buildings, given their availability in a wide range of

colours and finishes. |

| The

principles of ventilated rainscreen cladding systems are governed by BS

8200. The cladding is fixed back to the main support structure, forming a

relatively lightweight, colourful weather-resistant overcoat. The benefit of

this system is that any moisture, either ingress or humidity, is ventilated

out of the cavity, ensuring the insulation and the inner leaf of the

building are not affected by condensation. |

| A

range of different cladding systems are available in the UK, from thin film

aluminium or steel cassettes to fibre cement and glass fibre reinforced

polyester composite panels. Fixing systems also differ – designers can

select from wood, aluminium or steel stud in different thicknesses. But

which cladding system to choose? |

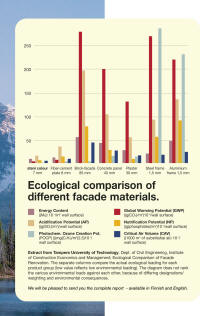

| A

study carried out by the Tampere University of Technology (Department of

Civil Engineering, Institute of Construction Economics and Management) in

Finland considered the environmental performance of the different cladding

systems and fixing methods in renovation projects, concentrating on the

impact of manufacture and use and maintenance. |

| Its

report, ‘Ecological Comparison of Façade Renovation’ helps designers

understand the environmental credentials of systems and therefore make

better-informed design and specification decisions. |

| And

its conclusion is unequivocal – glass fibre reinforced polyester composite

rainscreen panels ecologically outperform competitors in a number of tests,

ranging from Global Warming Potential (GWP) to Photochemical Ozone Creation

Potential. |

| The

study states: “The comparison shows that of those façade coating products

examined, glass fibre reinforced polyester composite has the least impacts

on environment, measured by the LCA factors.” |

| The study was

conducted using mainly Life Cycle Analysis developed by the Society of

Toxicology and Chemistry (SETAC) - transportation and the effects of the

energy required for renovation work were not taken into account. |

|

| The study was

conducted using mainly Life Cycle Analysis developed by the Society of

Toxicology and Chemistry (SETAC) - transportation and the effects of the

energy required for renovation work were not taken into account. |

| The Global Warming

Potential, Acidification Potential (AP), Nutrification Potential (NP),

Photochemical Ozone Creation Potential (POCP) and Critical Air Volume (CAV)

were compared and in each category glass fibre reinforced polyester panels

recorded the lowest – and therefore most advantageous – readings. Indeed, in

most cases, its results were less than half of its closest rival. |

| Take

for example the GWP results. Glass fibre reinforced polyester rainscreen

cladding panels 8mm thick returned a reading of 2,400g of CO2 per

square metre of wall surface. The next closest was 8mm-thick fibre cement

boards at 5,800g CO2/m². An 85mm brick façade was rated a massive

28,000g and a 130mm brick façade even greater at 39,000g CO2/m².

|

| As

mentioned previously, these results were mirrored in all but one of the

categories studied. Take the POCP results – 8mm glass fibre reinforced

polyester composite panels returned a score of 5mg CO2/m² of wall

surface. Its closest rival was again, 8mm fibre cement board with a score of

17mg CO2/m². Thin film aluminium cassette (1.5mm thick) scored

5,800mg CO2/m² and thin film steel cassette (1.5mm) 7,700mg CO2/m². |

|

Acidification Potential results also reinforced the sound environmental

performance of glass fibre systems, which scored 15g CO2/m² of

wall surface. Fibre cement board (8mm thick) was the next closest with a

rating of 35g CO2/m². Other results included 1.5mm-thick thin

film aluminium cassette – 136g CO2/m²; 85mm thick brick façade –

197g CO2/m² and 130mm thick brick façade – 274g CO2/m²

of wall surface. |

| When

Nutrification Potential was studied, glass fibre reinforced polyester

systems were virtually matched in performance by 30mm of plastering [0.6g

(phosphate)/m² of wall surface and 0.7g (phosphate)/m² of wall surface

respectively]. Fibre cement board scored 1.3g (phosphate)/m² and 40mm

concrete panel returned a reading of 2.5g (phosphate)/m². Brick façade

(130mm thick) topped the NP scale with 10.5g (phosphate)/m², with thin film

aluminium cassette of 1.5mm thickness scoring 9.1g (phosphate)/m². |

| Glass fibre

reinforced polyester systems also performed well in tests measuring the

energy contents of façade materials, registering the lowest score of 80MJ/m²

of wall surface. The highest was 130mm-thick brick façade, with a reading of

750MJ/m². |

|

| The study also

demonstrated that framing materials have an impact on environmental

performance. In every category, wood stud was the most ecologically-sound

fixing medium. For example in GWP tests, wood stud (30mm) scored 560g CO2/m²

of wall surface, compared with 30mm aluminium stud (8,800g CO2/m²)

and 30mm steel stud (7,600g (CO2/m²). |

| To conclude the

report, scientists looked at the ecological impacts of a modernised wall

structure during a period of 25 years from renovation. As would be expected,

the better insulated the property, the less ecological impact it caused. |

| The

report stated: “The most ecological alternative of those studied proved to

be a ventilated structure supported with impregnated long length wood,

insulated with 100mm thick glass wool and covered with glass fibre

reinforced polyester composite.” |