| Building Regulation Approved Document Part L has had quite

a dramatic effect on the heating and insulation requirements for

buildings, to reduce our consumption of fossil fuels and the flue gasses

that help to erode the Ozone Layer, that helps to control our climate. |

| But what effect has it had on the construction of

pitched tiled roofs? |

|

Insulation |

| Back in the 1950's when there was no requirement to

insulate roofs and heating was mostly fuelled by coal, the roof space was

only slightly colder than the rooms below. The lower room temperatures and

the natural ventilation up the chimney flue helped to reduce the quantity

of moisture in the air. As the thickness of insulation has increased, the

greater the difference in temperature between the roof space, above the

insulation, and the rooms below. This combined with the higher levels of

moisture that warm air could absorb, so the risk of condensation forming

in the roof space, or within the insulation, increases. The thicker the

insulation the greater the condensation risk. Installing a vapour check on

the underside of the insulation can reduce the risk, but under extreme

conditions it will not be eliminated. |

| What effect does thicker insulation have on roofing? |

- British Standard 5250 Code of practice for the Control of

Condensation in Buildings provides the best advice on what should be

done. If the insulation is placed between and above the horizontal

ceiling joists, the thicker the insulation the longer the corrugated

rafter trays that helps to maintain an air space between the

insulation and the underside of the underlay. The air space allows

ventilation air in and out at the eaves, to remove the cool air

containing excess water vapour before it can condense on the cold hard

surfaces in the roof, such as metal truss plates.

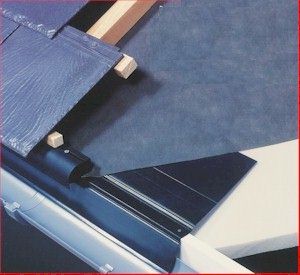

At the eaves where the roof insulation meets the outer wall, the

space diminishes down to the thickness of the rafter, which in most

cases will be less than 100mm. The depth of the rafter tray may further

reduce the rafter depth, which can be between 25 and 50mm. This may be

restricted still further by the wall plate being notched into the

rafter. The resulting space left for insulation may be less than 50mm.

The risk of condensation forming at this cold bridge area is high.

|

- If the insulation is positioned between the rafters, parallel with

the roof tiles the quantity of insulation may be greater in thickness

than the depth of the rafter. This may require an additional counter

batten to be fixed to the top or bottom of the rafter to increase the

insulation space. Alternatively a more expensive rigid insulation may

be used that being a better insulator can be thinner to achieve the

same thermal performance.

|

- What is more likely is rigid insulation board placed above the

rafters and counter battens fixed through it into the rafters below.

Because each timber rafter is below the insulation there are fewer

cold bridges and joints, making a thinner board more efficient.

At the ridge the insulation board needs to be mitred and sealed to

prevent a V shape cold bridge occurring. At the eaves the rigid

insulation needs to maintain continuity with the wall and will need

infill slabs to stand between the rafters to prevent a cold bridge at

the wall plate. With this arrangement any services, such as soil vent

pipes or roof windows that penetrate the rigid insulation will need to

be sealed to prevent a cold bridge.

|

|

Underlay |

| In many instances the rigid insulation manufacturers

recommend specific types of Vapour permeable underlay to ensure vapour

seeping through the joints in the boards is able to escape into the batten

cavity, and not condense on the underside of the underlay, and drain back

into the building.

The use of vapour permeable underlay to improve the thermal

performance of the roof will inevitably change the roof ventilation

requirements. If you do not have roof space ventilation below the underlay

then it will be needed above to ensure that there is a safe route for it

to escape into the outside air. To meet the ever more stringent

performance requirements, tiles are made to tighter tolerances (less gaps)

to allow them to be laid at lower rafter pitches. Less gaps means the risk

of water vapour condensing on the underside of the tiles and slates, or

worse still the timber battens, the greater the need for batten space

ventilation from eaves to ridge. Providing ventilation above the underlay

is best done with a 25mm over fascia vent at low level and a continuous

dry ventilated ridge system. If that is not possible, suitably spaced vent

tiles with shortened or no underside pipes.

|

|

The use of vapour permeable

underlays will allow the water vapour to pass into the batten cavity where

it will condense on the underside of the roof tile/slates. Without

ventilation at that point the battens and counter battens could be

affected in the long term.

|

|

|

Heating systems |

| The need for more efficient heating systems has seen the

number of Gas Condensing Boiler types increase. The act of extracting more

heat from the gas flame has resulted in lower flue gas temperatures. The

lower the flue gas temperature the greater the need for a fan flue system.

The cooler flue gasses, the higher content of water vapour and the higher

fan velocities have allowed the boiler manufacturers to reduce the

diameter of the flue and make them of plastic. |

| What has this to do with roofing? |

| Efficient building design requires the outer surface to be

reduced to a minimum, making terraced properties with room in the roof

more efficient. With less external wall surface, comes the compromise

between services and windows/doors. The answer is to locate the

gas-condensing boiler in the middle of the upper floor (airing cupboard)

and take the boiler flue directly up and out of the roof slope or ridge.

Some gas condensing boiler manufacturers are using standard inline vent

tiles, licensed for use as a gas condensing boiler terminal, rather than a

traditional flue pipe terminal. This may result in the choice of roof

covering being dictated by the heating boiler terminal specification,

rather than competitive price.

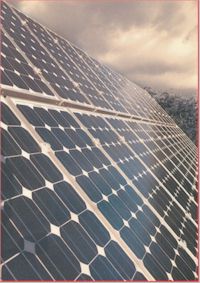

With the search for more efficient use of energy to heat

buildings and hot water, we will see more buildings with Solar Water

Heater or Photovoltaic panels that produce electricity, located on the

upper parts of south facing roof slopes. This is likely to result in more

systems being installed during construction or re roofing. At present the

systems available are not liked by planners as they are not visually

sympathetic to our traditional style of building, but some have been

designed to be integrated into the roof hiding all the brackets and pipes.

This trend combined with more compact housing units, may result in

complete roof slopes being nothing other than Solar Water Heater or

Photovoltaic panels.

|

| It will not be long before the

total south facing slope of most new roofs will be all solar panels. This

roof was designed and installed by Solar Century. |

|

|

Conclusion |

| Whilst at first sight the impact of Building Regulation

Approved Document Part L may not be very great on pitched roof coverings.

In the medium to long term there could be a significant effect on the

design and construction of roofs that will alter the specification and

construction of the roof. |