| The new Part C of the Building Regulations

"Site preparation and resistance to contaminants and moisture"

which was published in June this year comes into force in December (2004). |

|

| This paper summaries the recommendations of

the Regulation as it relates to metal roofing. |

| Part C2 of the Regulation states that the

roof of the building shall adequately protect the building and people who

use the building from harmful effects caused by: |

- Precipitation and wind-driven spray

- Interstitial and surface condensation

|

|

Section 6 gives guidance on technical solutions to achieve the requirements.

Note this section replaces Approved document F2 - Condensation in roofs.

|

|

Watertight

|

The first and obvious requirement is that the roof shall be watertight, in

the case of metal cladding the following documents are referred to

- BS CP 143 Code of Practice for sheet roof and wall coverings

- MCRMA Technical Paper 6 Profiled metal roofing design guide, revised

edition 1996

- MCRMA Technical Paper 9 Composite roof and wall cladding panel

design guide, 1995

|

|

Note that the MRCRMA Technical Paper 6 was revised in June 2004 for

more information and to download the paper go www.mcrma.co.uk.

|

| Interstitial Condensation

|

Three documents are referred to:-

- BS 5250:2002 Code of practice for the

control of condensation in buildings

- BS EN ISO 13788:2001 Hygrothermal

performance of building components and building elements. Internal

surface temperature to avoid critical surface humidity and

interstitial condensation. Calculation methods

- BRE Report BR 262 Thermal insulation:

avoiding risks, 2002

|

| To summarise the advice given in the above

publications. |

| Site assembled built-up systems |

- Provide a vapour control layer, either

the liner with laps sealed or separate vapour control layer minimum

500 gauge polyethylene. Ensure continuity of vapour control at

penetrations and junctions.

- Use ventilated filler strips at eaves

and ridge to allow ventilation of rib voids. (Ventilated fillers

should have an opening of not less then 5% of the rib void)

- For building with internal high humidity

such as swimming pools, give consideration to the use of a breather

membrane on top of the insulation. (Note that the membrane should

drain externally).

|

| The BRE report states that a breather membrane

is recommended where there is a calculated risk of condensate forming on

the underside of the out sheet and subsequently dripping. |

| Composite systems |

| Composite panels should be capable of being

sealed at side and end laps, to prevent moist air entering the joints

between panels |

| Surface Condensation

|

| To minimise surface condensation the roof

shall be designed and constructed so that the thermal transmittance

(U-value) does not exceed 0.35 W/m2K at any point |

| and |

| The junctions between elements and the

details of openings, are designed in accordance the MCRMA Technical Paper

14 Guidance for the design of metal roofing and cladding to comply with

approved document L2:2001, 2002. |

|

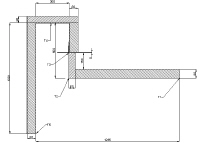

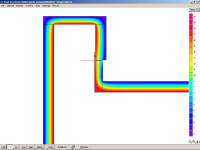

Details can been analysed using a 2D or 3D finite element thermal modelling

programs. These programs will give internal surface temperature at any point

in the detail. |

|

|

| The minimum temperature factor (fmin

factor) indicates the risk of surface condensation, the lower the value the

greater the risk.

ts = minimum surface temperature

te = external surface temperature

ti = internal surface temperature

|

The minimum values of the f-factor are

- Storage buildings - 0.3

- Offices, retail premises - 0.5

- Sports hall, kitchens - 0.8

- Swimming pools, laundries, breweries -

0.9

|

| Conclusion

|

| A number of calculations are likely to be

required for a building to comply with these regulations, minimum

U-values, condensation risk analysis and minimum temperature factors. For

help with these and other design calculations please contact me

here |