|

|

|

|

|

|

Sign up for our monthly news letter. |

|

|

|

The Egan agenda

is rapidly driving the construction industry into a new era of off-site

construction. But to date, roofs have been largely resistant to this trend.

Chris Thomas wonders why this should be so, and considers the range

|

|

|

Vencel Resil's Jablite

structural insulated roof system (above). Opstalan's hinged roof panels with

built-in rooflights (left). Installation of Kingspan's TEK Haus structural

insulated roof panels (below)

|

Building components are being delivered to site in ever larger modules:

hotel rooms, offices and whole class rooms now routinely arrive this way.

Yet in the majority of cases the roof is still constructed in the

traditional manner. Once a crane is required on site to lift the large

modularized components from the back of a truck into their final position,

it would seem logical to use the same crane to install the pitched roof.

On the majority of modular building

projects the pitched roof is either constructed using timber-trussed rafters

or unclad panel structures. Whilst some contractors have experimented with

assembling trussed rafter roofs on the ground, including felt and battens,

and lifting them into position with a crane, there is a lot of site work and

space required to achieve what is still a site produced roof construction.

Timber Roof Panels

The Dutch have embraced the use of factory produced timber roof

panels in a big way to suit their style of housing. Opstalan are one of

the better known manufacturers of structural diaphragm roofing panels. The

panels can be up to 2.4m wide and 10m long to span from ridge to eaves In

one unit. The panels comprise timber

rafters clad top and bottom with plywood panels filled with insulation. Some

come with battens, underlay and roof windows already installed, requiring

only the tiles to be installed. This form of roof construction works well on

long gable-to-gable buildings such as terraced houses with rooms in the

roof. The introduction of hips and valleys in the roof shape can be

accommodated, but will reduce the advantages of such a system. With the

hinged panel design, two panels joined at the ridge can be installed at the

same time with benefits in accuracy and speed.

|

|

| The

Jablite Roof Element system from Vencel Resil is a less complicated version

of the same thing with all panels 1.01m wide and In lengths between 3.92 and

7.52m. The panels can be supplied cut to a mitre at the ridge, but all have

square cut eaves. The narrower panels make forming hips and valleys a lot

easier, but a crane is still required to lift the panels into position. The

panels come with timber upstands, making it appear like a normal roof to a

roofer who will still need to fix underlay and battens prior to finishing

the roof with slates or tiles. With no trusses or beams, full use can be

made of the loft space.

Kingspan Insulation have recently

introduced the TEK Haus building system which incorporates structural

insulated roof panels similar to that of the Opstalan system, but without

the intermediate timber members to act as a cold bridge.

This makes for a very thermally efficient

panel, but relies on the bond of the OSB board skins with the rigid

urethane core to transmit some of the structural loads. The roof panels

come smooth and need to be covered with counter battens, underlay and

battens before the roof tiles can be fixed

|

Metal

Roof Panels

The use of Tactray 90 steel liner

trays from Hironville TAG, as used on commercial buildings, to reduce the

need for a timber roof structure on a steel framed building, requires a

lot of site work to achieve a quick roof substructure. The system is ideal

for wide span buildings. Once screwed together it makes a very secure

platform for the roofing work and a safe environment below to allow other

trades to work. The square cut ends to the sheets make hips and valleys

cumbersome, and the detailing of the ridge and eaves not as simple as with

timber trussed rafters, making the system ideal for large simple roof

designs.

An alternative approach is that of

the composite metal panel as promoted by Kingspan Building Products. This

uses two thin sheets of profiled steel sheet with rigid insulation

between. The composite panels can be installed quickly to produce a

weather-tight roof before battens are screw- fixed to the corrugations to

accommodate conventional tiles or slates. The integration of the panels

with a steel frame building makes this form of construction better suited

to wide span commercial buildings than to housing.

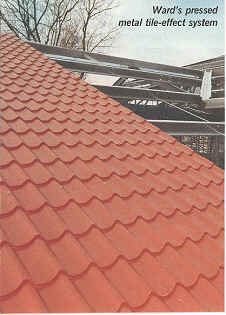

Ward Building Components has taken the composite

panel one stage further with the development of a composite metal panel

with the upper sheet pressed to represent an array of pan tiles, thus

providing an insulated panel with a tile-look finish. A single-fix

installation directly onto purlins eliminates the need for battens, roof

felt and separate insulation materials thus speeding up build times. Its

lightweight construction also enables structural support savings to be

made. The Ward system can accommodate hips and valleys but is best suited

to wide span steel frame buildings.

|

|

Instant

Roof

To truly take advantage of factory produced modular construction the

pitched roof also needs to arrive ready for installation with a minimum of

finishing on site. Hanson TIS, with its new Modular House, has developed

one solution to this problem, using four factory finished modules clamped

together on site. Two modules make the ground floor accommodation, the

other two form the first floor accommodation. The upper two units arrive

with a traditional tiled roof already installed. Once a crane has lifted

each unit into place, the lifting hooks are removed, the modules clamped

together, the flashing between the two sections of the building installed,

the plumbing and electrical connections checked and the building is ready

for occupation within a few hours.

This system appears to satisfy all the demands of developers,

planners, customers and the Health and Safety Executive. It is equally

suitable for executive homes and social housing, with the speed and

quality that would be almost impossible to achieve with any other modular

building system with a pitched roof.

The Future

With the rising cost of energy and

the need to control the deterioration of our environment, it will not be

long before legislation compels all south facing walls and roofs too

consist of solar panels to harness energy from the sun. Already the JOULE

European research project has produced PRIDE, a modular factory produced

solar roof panel ready to install. The system is similar to the Opstalan panel with the solar panels ready fitted and cabled ready to connect to a

suitable inverter.

I am sure the development of factory produced pitched

roofs will help to overcome the shortage of good roofing craftsmen, cut

delays due to bad weather, shorten snagging lists and reduce accidents on

site to a minimum. One way or another, factory produced roofs are long

overdue.

|

|