| Metal

roofing for industrial and commercial premises, with the familiar ribbed

profile from ridge to eaves, traditionally was complemented by metal

cladding with the profile running vertically from gutter towards the ground. |

| The

supporting structure for the roofing and vertical cladding is also similar

in practice, with the vertical primary steelwork crossed by horizontal

secondary steelwork. Skills acquired in roofing contracts are easily

transferred to installing vertical cladding. |

|

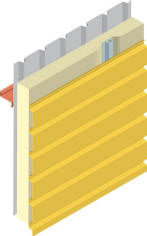

However, more and more building designs are incorporating horizontally

aligned wall profiles and panels in contrast to the vertical orientation of

the roofs. As a design statement, this has several effects, including

reduction of the apparent height and bulk of a monolithic building by

leading the eye horizontally. |

|

Although, this might appear to be a cladding system on its side, there are

several factors which the contractor should be aware of to ensure they are

incorporated into the contract specification and price. |

|

Loading the structure |

| One

factor to consider is loading the structure. |

| For site assembled

twin skin, using a typical "roof type" spacer grid for horizontal wall

cladding can lead to serious problems, as the spacer bracket is generally

designed to fit into the spacer bar at about 1m centres. However, because

the spacer has to stand vertically to carry horizontal sheeting, the spacer

brackets can only be fixed where the sheeting rails occur - usually at about

2m centres. Thus the spacer brackets are set too far apart and are too few

in number to carry the dead load of the cladding system. |

|

| Typical spacer

grid brackets rely on an interference fit in the spacer bar and this

attachment is designed to resist loads acting at right angles to the grid

bar, as happens in conventional roofing, rather than the parallel load

applied when the spacer grid is standing upright. |

| The

dead load of the cladding sheets have a tendency to pull the spacer bar

downwards, loading the bracket/bar joint against the interference fit which

in turn bends the bracket over. |

| Spacer

system suppliers have overcome this design problem by producing more

substantial "top hat" systems with screwed together connections that can

resist the dead and imposed loads better than the lighter "roof" systems.

|

|

Fixing the panels |

| A second factor to

consider is the placing of the fasteners. With a twin skin system, where the

gaps between portal frames may be too great for the panel length,

contractors may not be able to allow for sufficient fixings on the vertical

edges. Pull out under high wind suction, sealing and airtightness are all

potential points of difficulty. |

|

| Where horizontal

cladding is specified for aesthetic purposes, secret fixing is frequently

desirable. Contract difficulties can arise as a result of insufficient

fasteners or poor performance from fasteners not designed for high loading.

|

| A

better solution |

|

To minimise distortion and meet aesthetic needs,

composite (sandwich) cladding panels of insulation factory-adhered to metal

skins, are often considered the better choice for horizontal cladding

purposes.

|

| With

good inherent stiffness, perpendicular or lateral panel distortion is

minimised. In addition, many composite panels are designed for secret

fixing, with overlapping tongue and groove jointing which hide fasteners.

Low profile, self-drilling fasteners within the joints and using fasteners

with thread patterns designed to protect the insulation integrity, provide

rapid, secure fixing of panels. Self-coring fasteners can also provide

additional fastening security, with a minimal external appearance. |

| As

with any external envelope panel, composite panels also need the security of

25 year plus warranted austenitic stainless steel fasteners, to prevent the

risk of corrosion streaks on the once pristine fašade which would ultimately

lead to claims for redress. |

|

Additional considerations |

| If the

wall is specified as a fire wall to BS 476 part 22, any horizontal cladding

must follow the certified design detail with absolute rigour. The designs

are more complicated and costly than normal work, but the potential for fire

damage and even loss of life is so great that contractors who ignore the

detailed design will face severe consequences. |

|

Cladding contractors should also be aware of the special disciplines

required for installing other external wall protection such as rainscreen

cladding, which is often used in refurbishment projects. The essential

discipline when installing rainscreen cladding is to ensure absolute

flatness of the standoff support structure which carries the external skin

panels. Training by the system manufacturers and recruitment of specialist

fitters should be considered and is definitely recommended. |

| With

horizontal cladding, just as with rainscreen installation, investment of

time and thought into careful prior planning will help avoid pitfalls and

ensure profitable contracts. |

| For

further technical information, please contact: Peter Hamby, Product Manager

at SFS intec Ltd, 153 Kirkstall Road, Leeds. LS4 2AT Tel: 0113 2085 500,

Customer Service Fax: 0113 2085 573,or visit

www.sfsintec.biz/uk |