|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

In the roofing industry we all know about metal flashings,

especially lead sheet flashings. They have been with us since what feels

like the beginning of time, but only became common during the 20th

century. We all know that down to a true pitch of 30º the vertical lap

of lead sheet over any surface should be no less than 150mm, and as the

true pitch drops so the length of the vertical lap increases. But what

most people forget is that the horizontal lap also needs to increase as

the true pitch drops below 22.5º.

Horizontal laps

In most situations, such as a top edge abutment, a flashing will lap

onto the surface of the tiles by at least 150mm (depending upon the true

pitch, which is less than the rafter pitch), bridge across to the

abutment upstand, rise up the vertical face by at least 75mm, and either

tuck into brick joint, or be head nailed and lapped by a cover flashing

or another material, like vertical plain tiles or rendering. In this

situation the flashing changes pitch as it rises from the tiles to the

head nail fixing. But with some flashings one or more of the sections of

the flashing can be at a lower true pitch than the rest and it is the

true pitch of the lowest section of the flashing that should determine

the actual horizontal lap that is used.

If we were to take a chimney back gutter that is more than 2m

wide, using Code 4 lead the back gutter should be made in two pieces.

The joint between the two sections should not be lapped as the sole of

the back gutter is horizontal and therefore the joint should be a lead

covered timber core roll a lead roll. This will ensure the joint is

weathered and the lead can expand and contract without cracking.

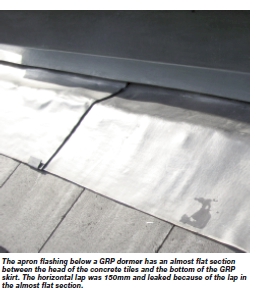

But there are instances where flashings can be almost

horizontal and are regularly installed with a 150mm horizontal lap,

which is incorrect as no lap joint should be formed below 11º. As an

example, the flashing at the change of rafter pitch on a mansard roof

may require the flashing on the steep lower slope to be 100mm horizontal

lap, but where the flashing passes under the tiles or slates on the

shallow upper roof slope the pitch of the flashing will quite often fall

below 11º and can be horizontal.

As we have seen with the chimney back gutter, below 11º

the flashing should not be lapped but formed in some other way. With a

mansard it would be inappropriate to use a lead covered timber core roll

joint. It may be tempting to run a very long length of lead flashing, or

weld sections of lead flashing together, so that there are no laps; this

should never be done as it will severely restrict the thermal movement

of the lead sheet, and it will prematurely crack. What is needed is a

welted joint.

Recommendations

The recommendations of the Lead Sheet Association are as follows:

Joints between flashings are usually laps. With

abutment flashings, the side laps should be not less than 100mm

increasing to 150mm for locations that are exposed to high wind and

rain. Flashings over 200mm girth will require a side lap of at least

200mm with the lap clipped. |

|

Where it states high wind and rain, this is

defined in BS 5534 as equal to, or more than, 56.5 litres of driving

rain per metre square, per spell, which is two minutes.

Where it mentions 200mm girth, this refers not to the

total width of the lead sheet but the lap of the flashing over the

surface below (head lap). This means that as soon as the true pitch of

the tiles or slates at an abutment drops below 22.5º (normally about

27.5º rafter pitch) the horizontal lap needs to increase to at least

200mm, and for the same pitch in an exposed location 250mm.

Whilst it would be logical to increase the horizontal

lap at the same rate as the vertical lap increases as the rafter pitch

drops down towards 11º, experience would suggest otherwise. This also

means that at true pitches below 11º the lead flashing should not be

lapped horizontally, and rolls, or welted seams should be used instead.

Conclusion

When installing a lead flashing, determine the horizontal lap by

measuring the true pitch of the lowest pitch of any section of the

flashing, and if below 11º, either raise that section, or use some other

jointing system between the sections of flashing. Between vertical and

22.5º true vertical pitch 100mm or 150mm horizontal lap (depending upon

the driving rain exposure of the roof) should be used, and between 11º

and 22.5º true vertical pitch the horizontal lap should be 200mm or

250mm depending upon the exposure of the roof.

Tips

- Where flashings lap under tiles, or

other sections of flashing, the horizontal lap requirements between

sections of flashings still applies.

- Lead sheet should be fully

supported. Be careful that there is not an unsupported gap between

the head of a tile, or slate, and the vertical upstand at an

abutment, where the flashing can develop into a trough.

- All horizontal laps should be lapped

away from the prevailing wind direction and should always be clipped

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|