|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

Wherever there is a room within a pitched

roof, there is likely to be at least one roof window installation. Each

window will be a penetration through the roof covering that will need to

be detailed and constructed correctly. Too often, the standard flashings

that are supplied are inadequate, or compromise the weathering of the

roof covering. The capabilities of the roof window flashings need to be

understood before they are used.

Types

There are two generic forms of roof window that are available, as

far as this discussion is concerned: those with an integral gutter and

flashing attached to the window frame, and those that have removable

flashings that differ with the type of roof covering that is used. Each

has its advantages and disadvantages.

The types that have an integral gutter around three sides,

and an apron flashing integral with the window frame, are more

watertight as they have no joints between the frame and the flashing,

but will not allow the use of soakers between double lap plain tiles or

slates, or an alternative lead cover flashing with interlocking tiles.

They are also either manufactured with a coated steel frame or an

injection moulded plastic frame; both of which have drainage channels of

a fixed size.

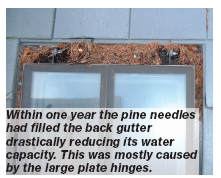

With the steel framed variety, there are large hinges which intrude into

the back gutter that trap snow and debris, and are heavier to open.

The windows with removable flashings tend to have a timber or extruded

plastic frame, to which the flashings are lapped and screwed, allowing

any alternative lead flashings to be used if the proprietary flashings

are not suitable. The gutter/flashing material is generally coated with

aluminium or zinc and needs to be supported, as it is very thin.

Rafter pitch

Generally, where there are rooms in the roof, the rafter pitch will

be fairly steep, but there are instances where, on a wide-span building

with a low pitch, roof windows are used to let light into the centre of

the building. While many roof window manufacturers claim that their roof

windows are suitable for rafter pitches down to 15°, it is often only

the window, not the flashings, which are suitable for the quoted minimum

rafter pitch.

Experience has shown that soaker installations

down to 22.5° can be trouble-free, while side channel flashings can be

trouble free down to 30°. The steeper the rafter pitch, the better.

Water run-off

The wider the roof window, the more rain-water will be collected in

the back gutter and drain down the side flashings of the roof window.

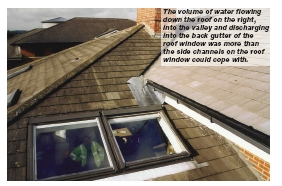

The greater the roof, and wall area above the

roof window, the greater the volume of rainwater that will drain into

the back gutter. But there is a limit to the amount of rainwater that

can be collected in a back gutter and flow down the gutter channels on

each side of the roof window, before the water floods over the edges of

the flashing.

Depending upon the pitch of the roof and the

actual size of the water channel, so the maximum area of roof draining

into the back gutter will vary. |

|

|

To be safe, the maximum roof area draining

into the back gutter at 25° rafter pitch should not exceed the

equivalent of 10m2 (horizontal), and at 40° this could rise

to 15m2 (horizontal). There are no tables provided by the

roof window manufacturers to assist designers, as roof window

manufacturers only make one size of roof flashing drainage channel and

could not offer an alternative if required.

Flashing laps

Around the roof window, the tiles lap onto the side and back gutter

flashings by approximately 75mm, depending on the manufacturer, while

the apron flashing laps over the course of tiles or slates.

With the flashings that are not integral, there are

laps between the apron and side channels, and the side channels and the

back gutter. The laps between the various sections of flashings are

mostly only 75mm and, if the lap is increased at the bottom, it reduces

the lap at the top by the same amount. At 30° the 75mm lap appears to

give no problems, while below 30° water can back up through the 75mm

lap, especially if the drainage channel is blocked with leaves.

Experience and testing undertaken by the Lead

Sheet Association has shown that, at 30° a 150mm flashing lap of an

apron flashing is needed to prevent water creeping up between the

flashing and the top surface of the tile, allowing for a nail hole to be

positioned 38mm down from the head of the tile. Below 30° the length of

the flashing needs to increase to a maximum of 270mm at 15° true pitch.

In almost every case the apron flashing supplied is not capable of

achieving a lap of greater than 150mm and, with some high profile tiles

such as unders and overs, the flashing may only achieve a 50mm lap on

the crown of the corrugation and may not stretch down to the trough of

the corrugation.

The flashing lap between the side channels and

the tiles, in most instances, relies upon an upstand against which the

tiles should rest. Under the tiles there is often a foam insert and an

upturn on the edge of the flashing. If installed correctly when new,

this will keep out most of the rainwater that will flow down the side

channels. However, after a few years the foam does become impregnated

with algae and can shrivel up leaving gaps through which rain can enter

and run down and across the underside of the edge tiles. This situation

is worse at shallow rafter pitches.

Tips

- Choose, or construct, the side

flashings with a drainage channel that is set in the thickness of

the battens (not above) to allow the edge tiles to sit flat, and not

kick up

- Ensure that the side drainage

channels can cope with the volumes of water that will drain into the

back gutter, and are kept away from high level valleys.

- Windows that are installed into

shallow roof pitches need to have longer flashings to suite the true

pitch of the tiles or slates.

The second part of this article looks at

the installation of the roof window flashings. |

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|