|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

It never ceases to

amaze me that a roof tiler will spend hours carefully laying out underlay

across the roof, lapping it correctly to prevent water on the underlay

penetrating through what is the secondary waterproof layer of the roof,

then proceed to cut unprotected holes through it for roof windows, pipes,

flues, vents, cables or safety anchors. Often the existence of a hole in

the underlay is only detected when a leak higher up the roof drains down

through the unprotected hole, damaging internal decorations.

Function

The underlay is an essential element of the roof as it is a:

- temporary roof covering against heavy rain during construction,

which lasts up until the final ridge or hip tile is secured.

- barrier to dust and snow that will penetrate the laps of the tiles.

When temperatures rise the melted snow runs down the underlay, whilst dust

will gravitate down the underlay more slowly depending upon the pitch of

the roof.

- collector of condensation that forms on the underside of the roof

during cold, damp weather.

- diaphragm to separate positive air pressure in the building from

acting on the underside of the roof covering during periods of high wind

suction.

A hole in the

underlay can contribute to a loss of tiles or slates under extreme wind

conditions.

- barrier to keep insects and small animals from entering the roof.

Small insects will always be able to enter the batten cavity, but if the

corrugations of a profiled tile are not closed off at the eaves, large

insects and small animals can easily get into the batten cavity from the

gutters.

Problem areas

- Underlay should not come within 25mm of a hot flue pipe. This is

less of a problem with the new design of condensing boiler, as flue pipe

temperatures are lower.

- Proprietary underlay seals glued to the underlay may not work with

banded bitumen underlay.

|

|

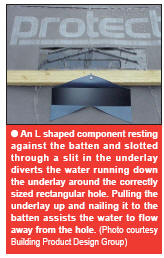

| - Few proprietary components for protecting a hole in underlay manage

to reinstate all the functions of the underlay and those that do tend to

be difficult to fit. The process of cutting an ‘X’ in the underlay and

folding back the loose sections around the pipe is common but not an

adequate solution. Often fixing instructions are ignored or the components

thrown away. This situation is not helped by supervision not detecting

that compliance with fixing instructions, drawings and specification has

not been achieved.

Advice

All holes through the underlay need to be protected. A tight fitting metall

or plastic seal, similar to a lead slate, lapped into the underlay tends

to be the most effective method of sealing the hole. If from inside the

roof you can see the underside of the roof covering around the pipe or

duct through the underlay, then protection to the hole is unlikely to be

adequate. Round pipes can be difficult to protect. Square ducts are

simpler, but have vulnerable corners. They can be sealed using lapped

sections of underlay laid up the face of the duct. If there is no pipe or

duct passing through the

underlay, protecting the hole is more difficult. Keep the number and size

of penetrations through the roof to an absolute minimum and as high up the

roof slope as possible.

|

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724 774. |

|