| Infrared Thermographic surveys are becoming a

necessity for all of us due to Part L. So what are they? |

| An "IRT" survey is essentially taking

pictures of your building. It is that simple. The only difference being,

the cameras see energy instead of light. Time on site is minimal with

little disruption. |

| Flat roofing is a good application for IRT, it

can show you exactly where insulation is missing, wet, or help find areas

with trapped water. There is no need to cut core samples into a perfectly

good roof and then risk applying a felt patch when thermography can take

an image of the roof. The biggest benefit of this type of survey is that

you learn about the entire roof - not just where you happen to take the

core samples. |

| What infrared can't tell you of course is what

the roof is made of. Ideally you want to use infrared in-conjunction with

core sampling to learn as much as possible about the roof. |

|

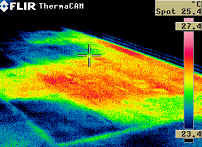

Wet insulation on flat roof - red areas. |

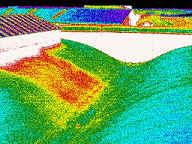

Normal picture of thermal image |

|

Barrel vaulted roof. Hot spot! |

Photo of thermal image to the left. |

| The IR equipment is now as portable and as easy

to use as a camcorder. The difficulty lies not in taking the images, but

in understanding them. For example: plant can generate lots of heat, which

will look exactly like wet insulation on a flat roof. Therefore the

thermographer must appreciate the building as a whole. |

| It should be noted that infrared is not perfect. There are

many pitfalls awaiting the inexperienced! |

|

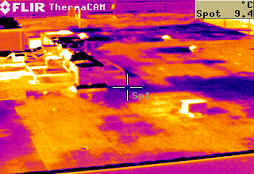

A badly ponding roof. |

Infrared images on their own can be very miss leading.

Insist on normal photographs to back up the thermal images. A simple

puddle on a roof reflecting the sky can lead to some obscure

interpretations.

|

| It is important that the IRT consultant is a building

specialist, is using the latest equipment and is properly trained in the

theory of infrared and thermodynamics. Mistakes can be expensive. |

| Unfortunately, the weather plays a big part in thermal

surveys. Too wet, too warm or even too windy and external surveys should

be avoided. |

| As such, there are certain conditions and times which should

be avoided for a thermal survey to yield useful results. The UK

Thermographic Association has issued guidelines to its members to try and

create uniformity within the industry. Basic principals apply: |

- A temperature difference of 10 degrees between the internal and

external is desirable as a minimum. The greater this difference is the

better.

- Wind speed should be less than 10 m/s.

- The roof surface should be dry.

- Surveys should be carried out in the evening / night-time, depending

on temperature.

|

| To understand the reasons for these rules you

must first understand what the thermal camera is detecting and also think

about the way heat will transfer from the building. |

| As we mentioned at the beginning of this

article the camera is only seeing energy - not sunlight. So why carry out

the survey at night? Although the camera can't see light, it can see the

effects of sunlight. So if the sun has heated up half of you roof or has

been reflected onto your roof, the camera will pick it up. Therefore a

thermal surveyor must allow the building to radiate it's own energy. By

letting the sun go down and waiting two hours the ambient temperature will

also have dropped outside - making the difference we mentioned above that

bit bigger. |

| Today's cameras allocate a colour to a

temperature. For instance red is generally hot and blue is usually cold.

The colours in between are then divided over the temperature span. (The

span is adjustable on the latest cameras). The bigger the temperature

difference the easier it is to detect. Saturated insulation may only be

1-2 degrees different from dry insulation. If the temperature difference

is large and the camera set up for the conditions, then wet insulation

will clearly show up as a totally different colour. Orange for wet, green

for dry for example. A small temperature difference, in the wrong

conditions and the same wet insulation may show up as one shade lighter

green against a slightly darker green good area. |

| Since the temperature differences we are

concerned with are very small it is important that the heat stays where it

is when it leaves the building. Therefore the lower the wind speed the

better. Wind has exactly the same effect on a roof as you do blowing on

your coffee - it cools it down - reducing the temperature difference we

are ideally looking for. See above! |

| Standing water or ballast on a roof makes a

thermal survey impossible. Water simply reflects the sky and leads to

meaningless images. Likewise, ballast holds moisture making surveys

impossible. A thermal survey on a ballasted roof will only show you damp

ballast, moss and ponding below the ballast. It gives you no indication of

the condition of the waterproofing. |

| Roofing is only one application for IRT in the

construction industry. Other applications include; |

- Delaminating render

- Cold bridge detection

- Insulation analysis

- Locating pipe-work in under-floor heating systems

|

| Part L has introduced IRT surveys for the first

time as a means of testing a building upon completion, though it remains

to be seen how many builders will take this option, or indeed how many

Local Authorities and clients will insist upon it. |

| If you would like to know more, please visit

our website at www.irtsurveys.com

or call 0870 240 3709. |