| As Roofing Manager

for Dow Building Solutions – manufacturer of STYROFOAM™ thermal insulation –

I know a roof may be only 2% of the overall budget of a build. However, I

also know that in terms of the usability, longevity and performance of a

structure, a roof’s value far outweighs its cost, meaning it’s vital that

the right decisions are made when it comes to system design, material choice

and installation. |

|

| With much of our

product going into large scale inverted flat roofing projects I spend a lot

of time on the roofs of schools, retail outlets and commercial office space

discussing delivery, installation and design challenges – but in recent

months long term performance and drainage issues have been dominating my

conversations as teams tackle decisions about thermal insulation choice for

inverted roofs. |

| Of

course considerations such as thermal efficiency requirements, product

availability, ease of installation and cost come first. However, besides

these requirements, there are two key things to remember when it comes to

specifying insulation for inverted flat roofs, and too often I see them

being considered at too late a stage: |

- Has the roof been designed with an

inverted roof solution in mind?

- Have all the relevant correction factors

necessary for a U-value calculation been taken into account?

|

| With

every client counting the cost of fuel – and so much importance being placed

on meeting energy standards and aiming for energy saving – it’s key that

such issues are taken into account in helping to allow an inverted roof

system to perform against required demands. |

|

Ensuring adequate drainage |

| Our

position at Dow is in line with BS 6229:2003: that an appropriate fall be

accommodated within the roof design and that the roof must be adequately

drained to prevent ponding. The location, size and number of rainwater

outlets should be designed in accordance with BS EN 12056-3:2000 and the

deck should be without deflections or depressions in which water may pond.

Drainage points should provide drainage at two levels: above the insulation

and at roof deck waterproofing levels. |

| We all

know that for cost reasons, ‘zero-pitch’ roofs are not uncommon. BBA

Information Bulletin No 4 advises that in such cases it is particularly

important to identify correct locations for drainage points and to ensure

that the drainage provided is sufficient and adequate. However, it is clear

that ANY roof should not have areas of ponding as a result of back falls -

and because insulation must not be permanently immersed or submerged in

water, they should be removed before insulation is installed. |

|

Various solutions are available which help to design out deflections without

resorting to the additional cost of laying additional screed – but such

design issues should be adequately tackled at an early stage and not left

until after the roof waterproofing has been chosen and installed. |

|

Thermal resistance |

|

European Technical Approval Guideline (ETAG) 031-1 – which sets out

performance requirements for inverted roof insulation kits – advises that

the declared thermal conductivity for insulation should be corrected due to

the special nature of the inverted roof application and the fact insulation

is being used in exposed rooftop conditions. |

| ETAG

031-1 states that possible water absorption over time is determined by

evaluating the performance of the insulation in respect of two mechanisms

for water absorption: by diffusion and post freeze/thaw. Corrected thermal

values are determined by assessing the total water absorption potential –

and it is these corrected values which ETAG 031-1 advises should be used in

any U-value calculations for inverted roof systems. |

|

ROOFMATETMSL-A, the STYROFOAM extruded polystyrene product we offer for

inverted roofs, has a closed cell structure which results in low water

pick-up over time, despite the rigorous conditions on exposed rooftops. For

example, tests shows that even after 300 cycles of freezing and thawing,

STYROFOAM will absorb less than 1% moisture by volume, one of the reasons it

continues to be specified for inverted roofs and other applications*. |

|

Rainwater cooling |

|

Rainwater able to reach the waterproofing layer on an inverted roof will

absorb heat from the underlying structure and affect the thermal performance

of a roof system. Therefore, the initial U-value of a roof system must also

be corrected by adding a rainwater correction factor according to Section 7

and Annex D.4 of BS EN ISO 6946:2007. |

| The

corrected U-value of an inverted roof will be dependent on the amount of

rainfall falling on the roof - which means it will be location specific -

and the proportion of rainwater which can reach the waterproof layer. |

| Dow

Building Solutions offers a water-flow reducing layer, ROOFMATE MK, which

reduces the proportion of rainwater reaching the waterproofing. Using

ROOFMATE MK in combination with ROOFMATE SL-A helps to minimise heat loss

due to rainwater cooling and therefore the amount of insulation required. |

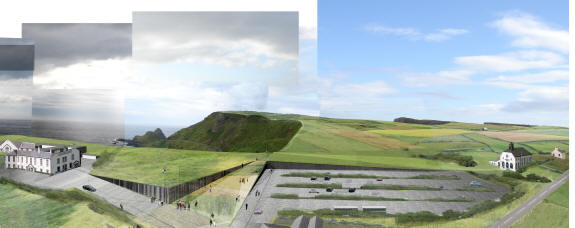

picture courtesy of heneghan.peng.architects |

| Taking

a holistic view |

|

STYROFOAM products are CE-marked, meaning specifiers, installers and

end-users can rely on the fact that declared lambda values are made in

accordance with BS EN 13164:2008 and BBA datasheet No 40/10. Additionally,

recent improvements to thermal conductivity of STYROFOAM-A across the

product range of 0.002 W/mK - combined with the material’s high compressive

strength and excellent moisture resistance – will no doubt continue to make

ROOFMATE a popular choice in inverted roofing. |

|

However, we know that statements about product performance alone are not

enough: decisions about inverted roof insulation choices need to take into

account lifetime performance in real conditions on a real roof, not just the

laboratory or factory – that’s where the true test begins. |

|

STYROFOAM products have been used for inverted roofs in the UK since the

1960s and well before that in North America. Specifiers and roofing

contractors can not only rely on that longstanding industry performance when

making decisions about insulation materials but helpful advice from our

technical desk when making appropriate U-value calculations which take

relevant factors into account: making it easier for everyone to get it right

from the start. |

| For

technical support or help calculating a U-value contact our Technical

Services Team on

fkltech@dow.com. Literature and a stockist list can be found at

www.styrofoam.co.uk.

|

| |

| |